REACH NEW HEIGHT...

OF PERFORMANCE AND PRODUCTIVITY

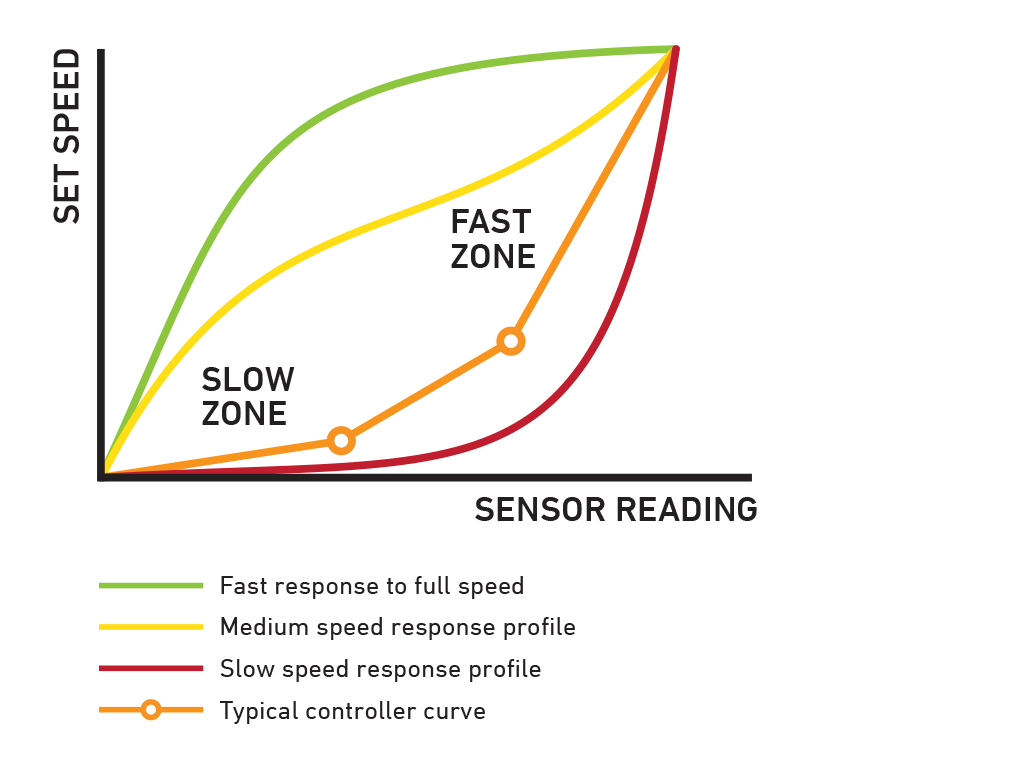

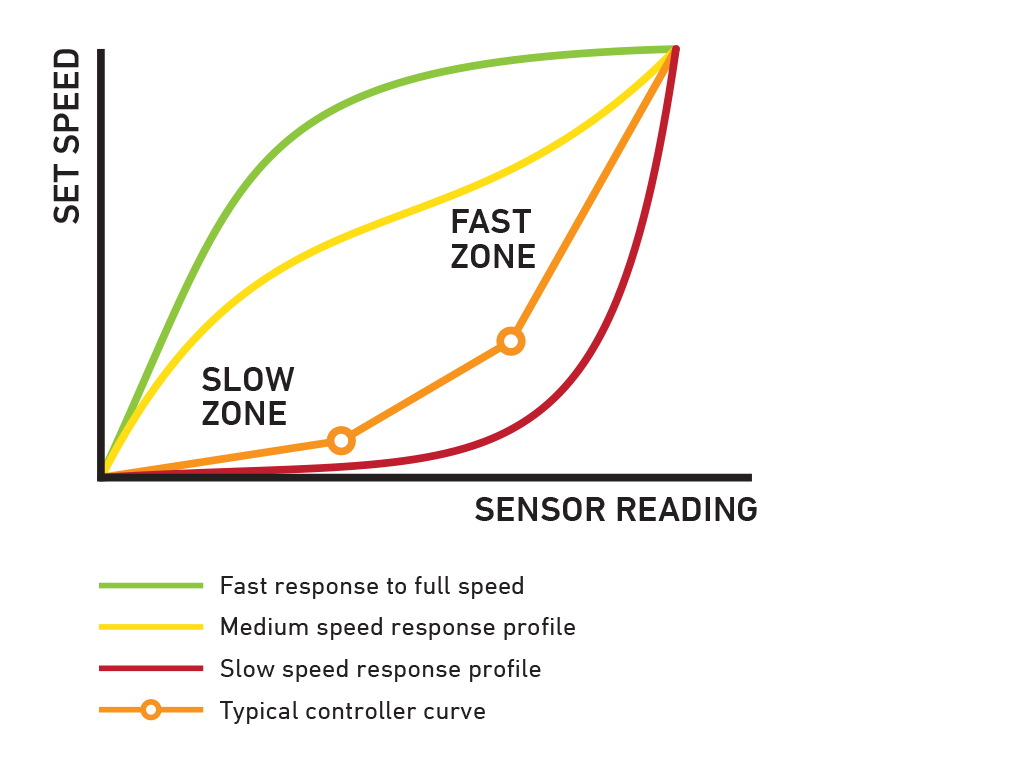

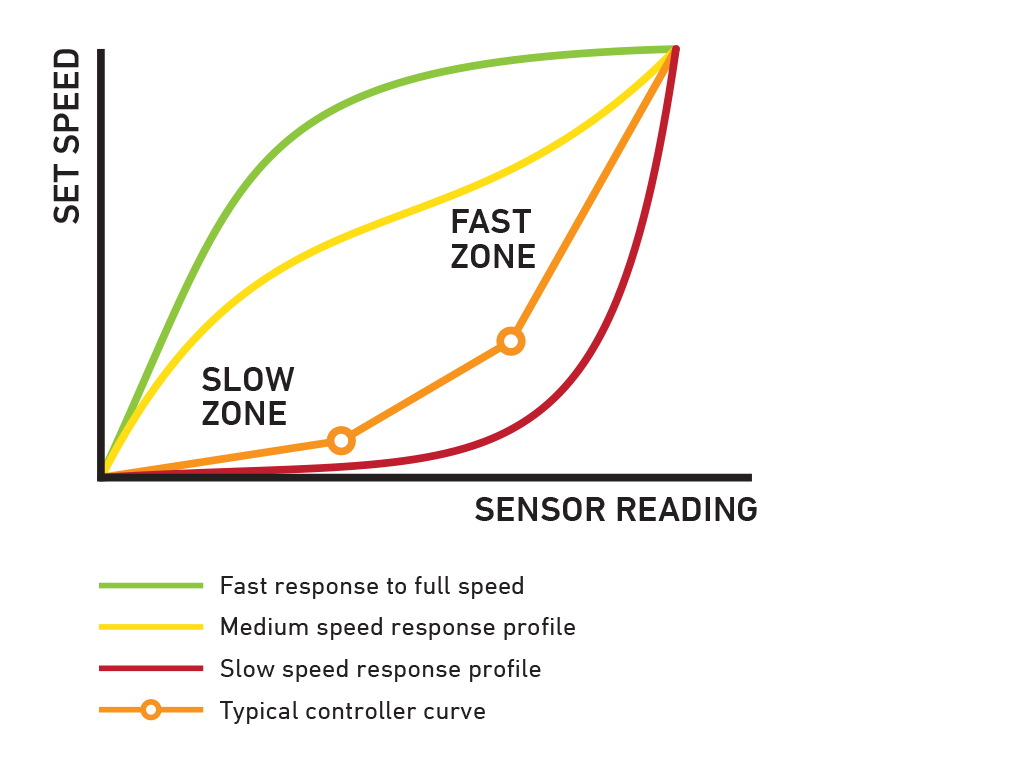

SENSiA EM is designed for effective and efficient operations. Its highly sensitive control system and progressive, modulated fingertip response curves allow operators to work with complete accuracy and confidence.

A choice of two operating modes means SENSiA EM can be adapted for different operators. PRO mode is ideal for experienced warehouse staff looking for optimum performance, while ECO mode puts novice operators at ease with natural handling. SENSiA EM can even be customised by a service engineer to ensure that the truck's settings suit specific needs.

The generous cabin space and ergonomic armrest ensure operators stay comfortable, safe and focused, even through the longest shifts.

| Model | Load Capacity |

|---|---|

| RB14N2HS | 1400 kg |

| RB14N2S | 1400 kg |

| RB16N2 | 1600 kg |

| RB16N2C | 1600 kg |

| RB16N2H | 1600 kg |

| RB16N2HC | 1600 kg |

| RB16N2HS | 1600 kg |

| RB16N2S | 1600 kg |

| RB20N2H | 2000 kg |

| RB20N2X | 2000 kg |

| RB25N2X | 2500 kg |

An intuitive driver-assist system for increased safety. Performance is managed according to steer angle and the velocity of foot and finger controls.

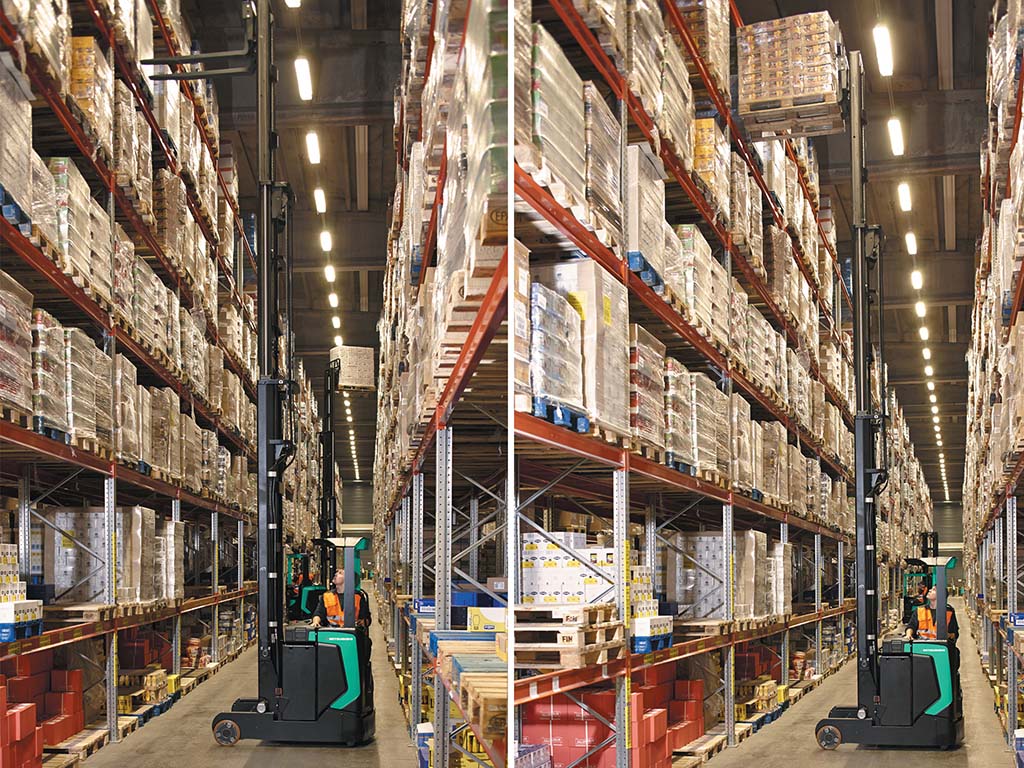

No delay waiting for the mast to stop swaying. Combined with the industry's most rigid mast, SENSiA delivers the highest cycling times available.

Its patented design creates a very strong, light and compact mast that offers lifting capacities and visibility: ensuring clear views to fork tips at all times.

Ffully protects your driver's left shoulder.

Delivers slick, smooth and controlled operation.

Fully supports the whole wrist, forearm, shoulder and back for maximum comfort, while ensuring optimal control of hydraulics.

Simply the brightest and longest-lasting available. Uses a fraction of the power consumed by alternatives - for long shift life.

This ensures battery checks and maintenance are kept safe, quick and easy.

Fully anti-glare, this serves as the machine's information hub. It's clear and easy-to-read and provides details of performance levels, operational indicators, battery discharge and usage hours.

Award-winning Active Sway Control (ASC) (option)

Delays caused by mast sway are reduced and performance is smoother and more stable.

Passive Sway Control

The chassis moves slightly to compensate for elevated load motion and dampen it.

Sensitive Drive System (SDS)

An intuitive driver-assist system for increased safety. Performance is managed according to steer angle and the velocity of foot and finger controls.

Revolutionary VisionMast

The operator gets forward vision.

Choice of two driving modes (ECO and PRO)

The truck's performance can be tailored for enhanced performance or extended shift life.

Ergonomic armrest

Adjustable and matches natural operating position to reduce fatigue.

360-degree steering

The operator can keep the truck in constant motion - saving seconds on every turn.

Fingertip control system

Patented with modulated response curves and optimised for natural movement with effortless control.

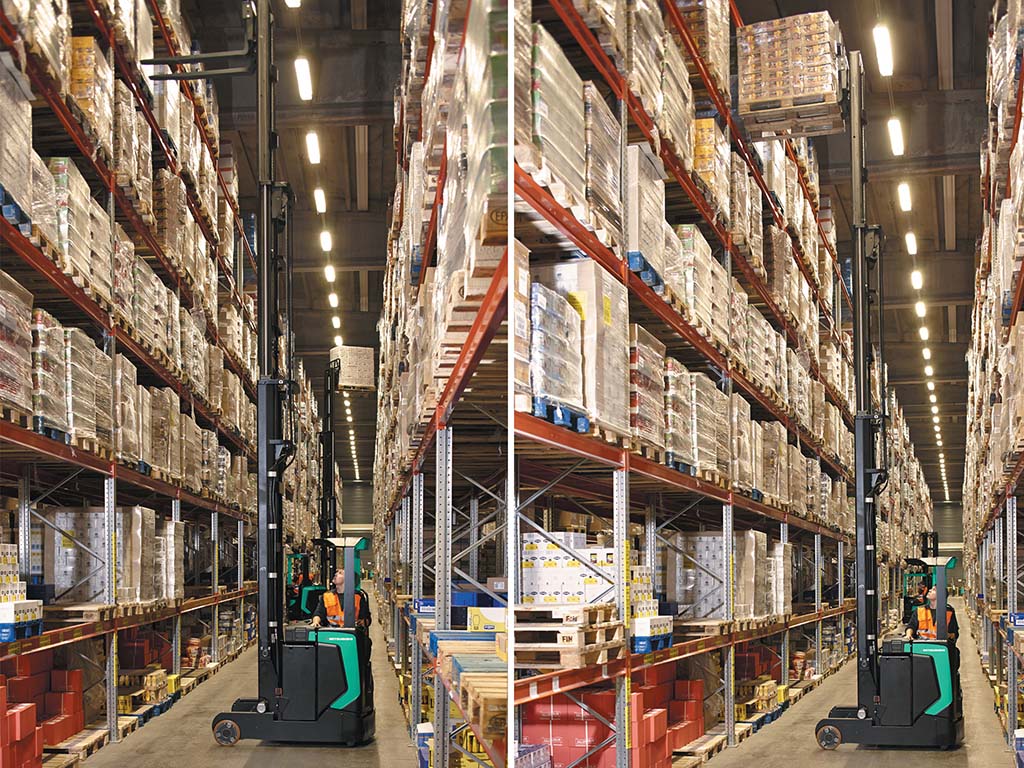

Spacious and comfortable cabin, clear view and fast, accurate fork positioning

This all helps to increase productivity and reduce risks of driver fatigue - even on the longest shifts.

The Mitsubishi VisionMast has unrivalled forward views thanks to its revolutionary design, allowing for safer and more precise operations.

Typically, hydraulic cylinders obstruct forward vision while travelling. By enclosing them within the first stage of the mast, visibility is maximised. With its low weight and high strength, the VisionMast has substantially increased residual capacities.

To get the most from operator and machine our centralised system for AC control uses advanced intelligent control, plus the latest MOSFET and heat dissipation technology for maximum performance and energy efficiency.

Offering high power for excellent traction and ramp performance, it provides smooth, quiet and controlled operation, extended shift lengths and reduced maintenance requirements.

The revolutionary SDS (Sensitive Drive System) employs ground-breaking software that allows the truck to sense - from the very first touch - exactly how a driver wishes to operate.

Performance is managed according to steer angle and the velocity of foot and finger controls.

The unique fully adjustable, full-length armrest supports the arm and palm to keep operators safe and comfortable, reducing the risk of RSIs associated with intensive operations.

Ideal for applications where precise control is needed, they can even be operated using heavy protective gloves.

Programmable sensitivity

Meets the needs of different applications and operators.

Touch-sensitive fingertip controls

Spring-loaded for a natural feel. The lighter the touch, the finer the control.

Modulated response curves

Optimised for natural movement - for precise, effortless control.

To ensure maximum productivity at any height, this model is equipped with Passive Sway Control.

This feature dampens the elevated load motion that can occur when carrying loads at height.

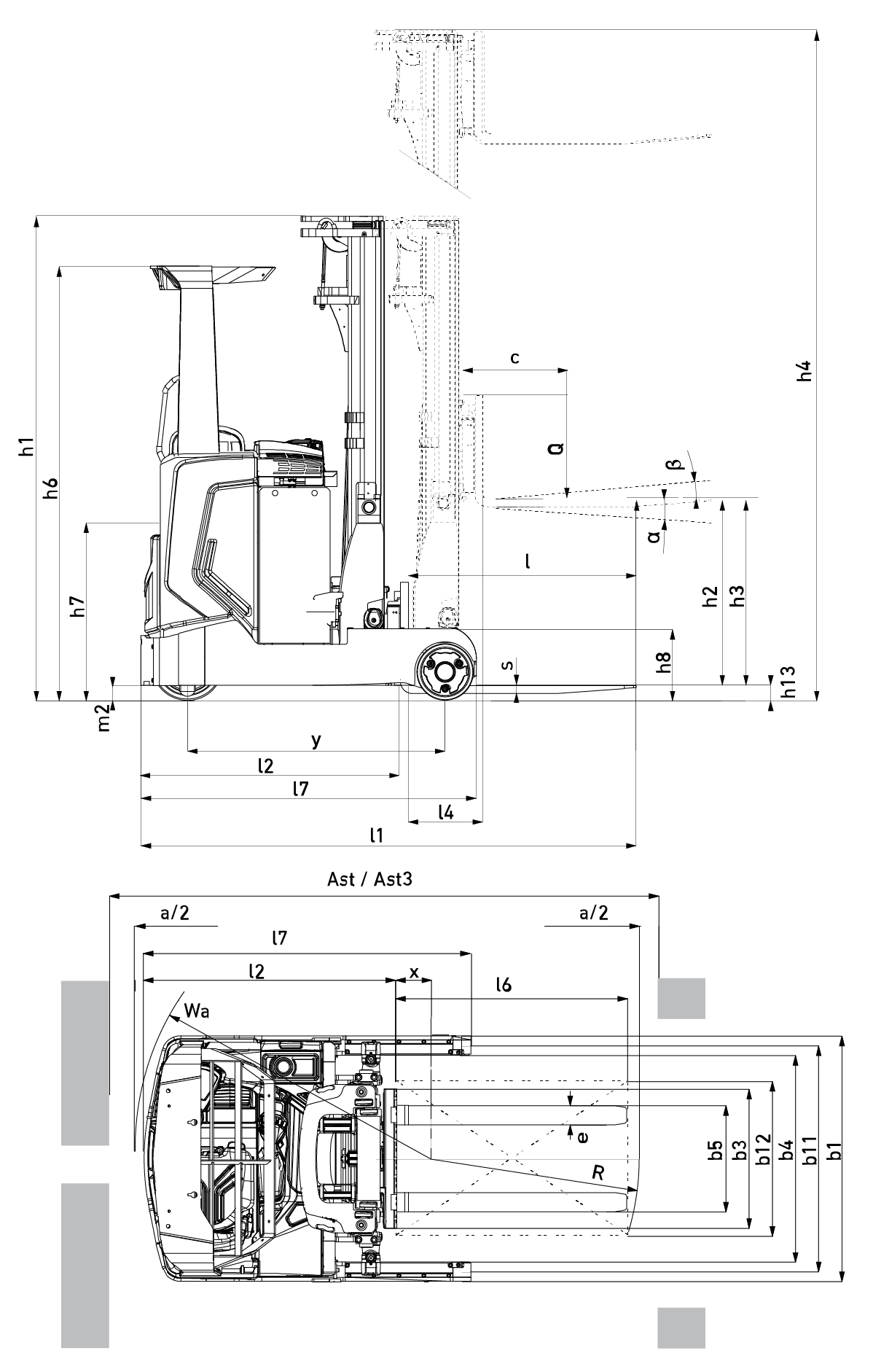

| Characteristics | ||||||||||||||

| 1.2 | Manufacturer's model designation | RB14N2HS | RB14N2S | RB16N2 | RB16N2C | RB16N2H | RB16N2HC | RB16N2HS | RB16N2S | RB20N2H | RB20N2X | RB25N2X | ||

| 1.3 | Power source: (battery, diesel, LP gas, petrol) | Battery | Battery | Battery | Battery | Battery | Battery | Battery | Battery | Battery | Battery | Battery | ||

| 1.4 | Operator type: pedestrian, (operator)-standing, -seated | Seated | Seated | Seated | Seated | Seated | Seated | Seated | Seated | Seated | Seated | Seated | ||

| 1.5 | Load capacity | Q | kg | 1400 | 1400 | 1600 | 1600 | 1600 | 1600 | 1600 | 1600 | 2000 | 2000 | 2500 |

| 1.6 | Load centre distance | c | mm | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 |

| 1.8 | Load wheel axle to fork face (forks lowered) | x | mm | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ |

| 1.9 | Wheelbase | y | mm | 1300 | 1300 | 1350 | 1400 | 1350 | 1400 | 1300 | 1300 | 1500 | 1500 | 1500 |

| Weight | ||||||||||||||

| 2.1b | Truck weight without load, with maximum battery weight | kg | 5497* | 4770* | 5245* | 4909* | 5971* | 5639* | 5497* | 4991* | 6170* | 6665* | 6756* | |

| 2.3 | Axle loadings without load & with maximum battery weight, drive/load side | kg | 2208 / 1889 | 1925 / 1445 | 1995 / 1650 | 1840 / 1469 | 2275 / 2096 | 2114 / 1925 | 2208 / 1889 | 1925 / 1466 | 2200 / 1970 | 2385 / 2280 | 2231 / 2025 | |

| 2.4 | Axle loading, mast forward, with nominal load, drive/load side | kg | 704 / 4793 | 605 / 4165 | 616 / 4628 | 510 / 4398 | 719 / 5252 | 614 / 5024 | 704 / 4793 | 590 / 4402 | 675 / 5495 | 445 / 6220 | 440 / 6315 | |

| 2.5 | Axle loading, mast retracted, with nominal load, drive/load side | kg | 1873 / 3624 | 1590 / 3180 | 1626 / 3618 | 1484 / 3425 | 1906 / 4065 | 1759 / 3880 | 1873 / 3624 | 1570 / 3422 | 1785 / 4385 | 1855 / 4810 | 1712 / 5043 | |

| Wheels, Drive Train | ||||||||||||||

| 3.1 | Tyres: PT=Power Thane, Vul=Vulkollan, drive/load side | Vul | PT | PT | PT | Vul | Vul | Vul | PT | Vul | Vul | Vul | ||

| 3.2 | Tyre dimensions, drive side | 0360 × 140 | 0360 × 140 | 0360 × 140 | 0360 × 140 | 0360 × 140 | 0360 × 140 | 0360 × 140 | 0360 × 140 | 0360 × 140 | 0360 × 140 | 0360 × 140 | ||

| 3.3 | Tyre dimensions, load side | 0285 × 75 | 0285 × 75 | 0285 × 130 | 0285 × 75 | 0285 × 130 | 0285 × 75 | 0285 × 75 | 0285 × 75 | 0285 × 130 | 0285 ×130 | 0285 ×130 | ||

| 3.5 | Number of wheels, drive/load side (x=driven) | 2 / 1x | 2 / 1x | 2 / 1x | 2 / 1x | 2 / 1x | 2 / 1x | 2 / 1x | 2 / 1x | 2 / 1x | 2 / 1x | 2 / 1x | ||

| 3.7 | Track width (centre of tyres), load side | b11 | mm | 1195 | 1195 | 1140 | 1025 | 1140 | 1025 | 1195 | 1195 | 1140 | 1310 | 1310 |

| Dimensions | ||||||||||||||

| 4.1 | Fork tilt, forwards / backwards | a / b | ° | 2/ 4 | 2 / 4 | 2 / 4 | 2 / 4 | 2 / 4 | 2 / 4 | 2 / 4 | 2 / 4 | 2 / 4 | 2 / 4 | 2 / 4 |

| 4.2 | Height | h1 | mm | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ |

| 4.3 | Free lift (see tables) | h2 | mm | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ |

| 4.4 | Lift height (see tables) | h3 | mm | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ |

| 4.5 | Height with mast extended | h4 | mm | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ |

| 4.7 | Height to top of overhead guard | h6 | mm | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 |

| 4.8 | Seat height | h7 | mm | 1030** | 1030** | 1030** | 1030** | 1030** | 1030** | 1030** | 1030** | 1030** | 1030** | 1030** |

| 4.10 | Height of support legs | 360 | 360 | 360 | 360 | 360 | 360 | 360 | 360 | 360 | 360 | 360 | ||

| 4.15 | Fork height, fully lowered | h13 | mm | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 |

| 4.19 | Overall length | l1 | mm | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ |

| 4.20 | Length to fork face (includes fork thickness) | l2 | mm | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ |

| 4.21 | Overall width | b1/b2 | mm | 1270 | 1270 | 1270 | 1100 | 1270 | 1100 | 1270 | 1270 | 1270 | 1440 | 1440 |

| 4.22 | Fork dimensions (thickness, width, length) | s,e,l | mm | 40 / 100 / 1150 | 40 / 100 / 1150 | 40 / 100 / 1150 | 40 / 100 / 1150 | 40 / 100 / 1150 | 40 / 100 / 1150 | 40 / 100 / 1150 | 40 / 100 / 1150 | 50 / 100 / 1150 | 50 / 100 / 1150 | 50 / 100 / 1150 |

| 4.23 | Fork carriage to DIN 15 173 A/B/no | FEM 2A | FEM 2A | FEM 2A | FEM 2A | FEM 2A | FEM 2A | FEM 2A | FEM 2A | FEM 2A | FEM 2A | FEM 2A | ||

| 4.24 | Fork carriage width | b3 | mm | 720 | 720 | 720 | 720 | 720 | 720 | 720 | 720 | 720 | 720 | 720 |

| 4.25 | Outside width over forks (minimum/maximum) | b5 | mm | 315-710 | 315-710 | 315-710 | 315-710 | 315-710 | 315-710 | 315-710 | 315-710 | 315-710 | 315-710 | 315-710 |

| 4.26 | Inner width of support legs | b4 | mm | 1070 | 1070 | 900 | 900 | 900 | 900 | 1070 | 1070 | 900 | 1070 | 1070 |

| 4.28 | Mast reach | l4 | mm | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ |

| 4.32 | Ground clearance at centre of wheelbase, (forks lowered) | m2 | mm | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 |

| 4.33a | Working aisle width (Ast) with 1000 × 1200 mm pallets, load crosswise, platform up/down | Ast | mm | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ |

| 4.33b | Working aisle width (Ast3) with 1000 × 1200 mm pallets, load crosswise, platform up/down | Ast3 | mm | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ |

| 4.34b | Working aisle width (Ast3) with 800 × 1200 mm pallets, load lengthwise, platform up/down | Ast3 | mm | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ |

| 4.35 | Turning circle radius | Wa | mm | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ |

| 4.36 | Minimum distance between centres of rotation | b13 | mm | 1693 | 1693 | 1793 | 1793 | 1793 | 1793 | 1693 | 1693 | 1893 | 1893 | 1893 |

| Performance | ||||||||||||||

| 5.1 | Travel speed, with/without load | km/h | 12 / 12 | 12 / 12 | 12 / 12 | 12 / 12 | 14 / 14 | 12 / 12 | 12 / 12 | 12 / 12 | 14 / 14 | 11 / 14 | 11 / 14 | |

| 5.2 | Lifting speed, with/without load | m/s | 0.4 / 0.7 | 0.4 / 0.65 | 0.4 / 0.65 | 0.4 / 0.65 | 0.4 / 0.7 | 0.4 / 0.7 | 0.4 / 0.7 | 0.4 / 0.65 | 0.4 / 0.7 | 0.4 / 0.7 | 0.3 / 0.7 | |

| 5.3 | Lowering speed, with/without load | m/s | 0.55 / 0.5 | 0.55 /0.5 | 0.55 / 0.5 | 0.55 / 0.5 | 0.55 / 0.5 | 0.55 / 0.5 | 0.55 / 0.5 | 0.55 / 0.5 | 0.55 / 0.5 | 0.55 / 0.5 | 0.55 / 0.5 | |

| 5.4 | Reach speed. with/without load | m/s | 0.2 / 0.2 | 0.2 / 0.2 | 0.2 / 0.2 | 0.2 / 0.2 | 0.2 / 0.2 | 0.2 / 0.2 | 0.2 / 0.2 | 0.2 / 0.2 | 0.15 / 0.15 | 0.15 / 0.15 | 0.15 / 0.15 | |

| 5.8 | Maximum gradeability, with/without load | s | 10 / 15 | 10 / 15 | 10 / 15 | 10 / 15 | 10 / 15 | 10 / 15 | 10 / 15 | 10 / 15 | 10 / 15 | 10 / 15 | 10 / 15 | |

| 5.9 | Acceleration time (10 metres) with/without load | s | 4.8 / 4.4 | 5.0 / 4.5 | 5.0 / 4.5 | 5.0 / 4.5 | 4.8 / 4.6 | 4.8 / 4.8 | 4.8 / 4.4 | 5.0 / 4.5 | 4.8 / 4.4 | 5.2 / 4.4 | 5.2 / 4.4 | |

| 5.10 | Service brakes (mechanical /hydraulic /electric /pneumatic) | Electric | Electric | Electric | Electric | Electric | Electric | Electric | Electric | Electric | Electric | Electric | ||

| Electric Motors | ||||||||||||||

| 6.1 | Drive motor capacity (60 min. short duty) | kW | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | |

| 6.2 | Lift motor output at 15% duty factor | kW | 14 | 10 | 10 | 10 | 14 | 14 | 14 | 10 | 14 | 14 | 14 | |

| 6.4 | Battery voltage/capacity at 5-hour discharge | V/Ah | 48-620 / 775 | 48-465 / 620 / 775 | 48-465 / 620 / 775 | 48-620 / 775 | 48-620 / 775 | 48-620 | 48-620 / 775 | 48-465 / 620 / 775 | 48-620 / 775 / 930 | 48-620 / 775 / 930 | 48-620 / 775 / 930 | |

| 6.5 | Battery weight | kg | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | |

| Miscellaneous | ||||||||||||||

| 8.1 | Type of drive control | Stepless | Stepless | Stepless | Stepless | Stepless | Stepless | Stepless | Stepless | Stepless | Stepless | Stepless | ||

| 8.4a | Level of noise at the ear level of the driver according to EN 12 053:2001 and EN ISO 4871 in work LpAZ | dB(A) | 63 | 63 | 63 | 63 | 63 | 63 | 63 | 63 | 63 | 63 | 63 | |

| 8.4b | Level of noise at the ear level of the driver according to EN 12 053:2001 and EN ISO 487, drive/lift/idle LpAZ | dB(A) | 61 /69 / 48 | 61 / 69 / 48 | 61 / 69 / 48 | 61 / 69 / 48 | 61 / 69 / 48 | 61 / 69 / 48 | 61 / 69 / 48 | 61 / 69 / 48 | 61 / 69 / 48 | 61 / 69 / 48 | 61 /69 / 48 | |

| 8.6a | Whole-body vibration (EN 13 059:2002) | m/s² | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 | 0.31 | |

| 8.7a | Hand-arm vibration (EN 13 059:2002) | m/s² | < 2.5 | < 2.5 | < 2.5 | < 2.5 | < 2.5 | < 2.5 | < 2.5 | < 2.5 | < 2.5 | < 2.5 | < 2.5 | |

| 10.7 | Sound pressure level at the driver's seat | dB (A) | 712) | 672) | 662) | 662) | 632) | 632) | 632) | 672) | 632) | 632) | 632) |