PUTERE MARE

ECONOMIE EXCEPȚIONALĂ

Fiind cele mai mari modele electrice, stivuitoarele din gama Mitsubishi Forklift Trucks, seria de contrabalansare electrică FB60-120N(H) oferă o putere uriașă, fără compromisuri la performanță și precizie. Cea mai bună accelerare din clasă și utilizarea inteligentă a energiei reprezintă o completare extrem de eficientă pentru orice șantier de lucru.

Fiecare model are o cabină etanșată cu cauciuc care minimizează microvibrațiile și reduce zgomotul în cabină, creând un mediu mai confortabil, fără stres pentru șofer. Vizibilitatea excelentă înainte și camerele din spate asigură o operare mai sigură și mai sigură.

O alternativă ideală la stivuitoarele cu motor IC, modelele din seria FB60-120N(H) sunt caii de muncă grei pe care vă puteți baza. O opțiune joasă de protecție deasupra capului este disponibilă pentru toate modelele – chiar și până la 12 tone – permițând stivuitorului să fie utilizat în aplicații pentru containere pentru o mai mare flexibilitate a flotei.

| Model | Capacitate de încărcare |

|---|---|

| FB60N | 6000 kg |

| FB60NH | 6000 kg |

| FB65N | 6500 kg |

| FB65NH | 6500 kg |

| FB70N | 7000 kg |

| FB70NH | 7000 kg |

| FB80N | 8000 kg |

| FB80N-900 | 8000 kg |

| FB80NH | 8000 kg |

| FB80NH-900 | 8000 kg |

| FB90N | 9000 kg |

| FB90NH | 9000 kg |

| FB100N | 10000 kg |

| FB100NH | 10000 kg |

| FB120NH | 12000 kg |

Mișcările de balansare a catargului sunt amortizate de șasiu, permițând operatorilor să ridice cu încredere la înălțimi mari. Această stabilitate sporită nu numai că asigură siguranța operatorului și a oricăror materiale ridicate, dar contribuie și la eficiența generală a operațiunii.

Zgomotul general din interiorul cabinei este de doar 65 dB - care este similar nivelului normal de conversație - oferind un mediu liniștit și lipsit de stres în care operatorul se poate concentra asupra sarcinii în cauză.

Acest lucru oferă o mai bună aderență și manevrabilitate, în special în spațiile înguste, deoarece stivuitorul se poate întoarce rapid și ușor pe loc. Această manevrabilitate ridicată se traduce prin eficiență și productivitate crescute. (numai modelele H)

Nivelurile ridicate de zgomot au fost recunoscute de mult timp ca un factor major care contribuie la oboseala operatorului. La 65 dBA, acesta este cel mai scăzut din clasa sa și ajută operatorul să fie mai confortabil în timpul schimburilor.

Configurarea bateriei duble (2 baterii de 48 V, câte una pe fiecare parte a stivuitorului) simplifică procesul de înlocuire a bateriei permițând schimburi rapide și ușoare utilizând un transpalet sau o contrabalansare.

Având o înălțime a scaunului similară cu cea a multor stivuitoare cu motor IC oferă avantaje ergonomice semnificative. Reduce solicitarea fizică a operatorilor, minimizând efortul necesar pentru a accesa scaunul șoferului, reducând oboseala și efortul în timpul schimburilor. De asemenea, facilitează o tranziție pentru operatorii obișnuiți cu stivuitoarele cu motor IC, deoarece mediul de lucru va fi familiar.

Direcție pe patru roți (4WS)

Motoarele de antrenare ale punții din față se rotesc în direcții separate pentru o aderență mai bună și o manevrare precisă. Axa din spate se deplasează la 101°, cu motoare duble de antrenare pentru o virare instantanee, lină pe loc și fără „împingere” inițială. Acest lucru oferă o manevrabilitate excelentă în spații înguste. (numai modelele H)

Ridicare cu zgomot redus

Pompa hidraulică silențioasă contribuie la un nivel general scăzut de zgomot (doar 65 dB).

Afișaj clar, informativ

Color și ușor de citit din toate unghiurile. Chiar și în lumina directă a soarelui. Poziționat perfect pentru referință dintr-o privire, fără a reduce vizibilitatea de jur împrejur.

| Caracteristici | ||||||||||||||||||

| 1.2 | Denumirea modelului producătorului | FB60N | FB60NH | FB65N | FB65NH | FB70N | FB70NH | FB80N | FB80N-900 | FB80NH | FB80NH-900 | FB90N | FB90NH | FB100N | FB100NH | FB120NH | ||

| 1.3 | Sursa de alimentare: (baterie, motorină, gaz LP, benzină) | Electric | Electric | Electric | Electric | Electric | Electric | Electric | Electric | Electric | Electric | Electric | Electric | Electric | Electric | Electric | ||

| 1.4 | Modul de operare: pieton, (operator)-în picioare, -așezat | Aşezat | Aşezat | Aşezat | Aşezat | Aşezat | Aşezat | Aşezat | Aşezat | Aşezat | Aşezat | Aşezat | Aşezat | Aşezat | Aşezat | Aşezat | ||

| 1.5 | Capacitate de încărcare | Q | kg | 6000 | 6000 | 6500 | 6500 | 7000 | 7000 | 8000 | 8000 | 8000 | 8000 | 9000 | 9000 | 10000 | 10000 | 12000 |

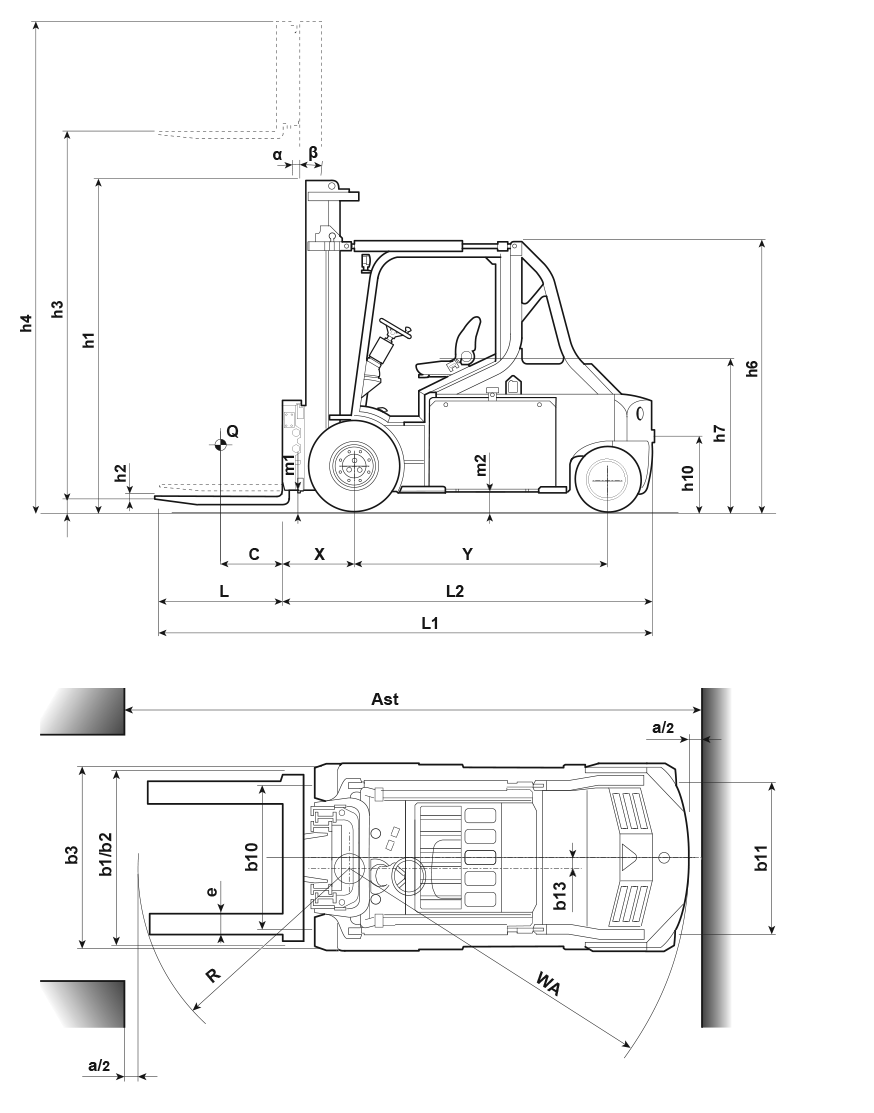

| 1.6 | Distanța centrului de încărcare | c | mm | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 900 | 600 | 900 | 600 | 600 | 600 | 600 | 600 |

| 1.8 | Distanța de încărcare, axă-fața furcii (furcile coborâte) | x | mm | 650 | 650 | 650 | 650 | 650 | 650 | 700 | 700 | 700 | 700 | 720 | 720 | 720 | 720 | 730 |

| 1.9 | Ampatament | y | mm | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 | 2550 | 2550 | 2550 | 2630 | 2550 | 2550 | 2630 | 2630 | 2980 |

| Greutate | ||||||||||||||||||

| 2.1 | Masă utilaj fără încărcătură, baterie cu masă maximă | kg | 10260 | 10260 | 10430 | 10430 | 10770 | 10770 | 12095 | 12095 | 12095 | 14175 | 13425 | 13425 | 14175 | 14425 | 16105 | |

| 2.2 | Încărcare pe axe cu sarcină maximă, față/spate (catarg simplex, înălțime de ridicare minimă) | kg | 14523 / 1737 | 14523 / 1737 | 15316 / 1614 | 15316 / 1614 | 16124 / 1646 | 16124 / 1646 | 18670 / 1425 | 18670 / 1425 | 18670 / 1425 | 20356 /1819 | 20780 / 1645 | 20780 / 1645 | 20356 / 1819 | 22678 / 1747 | 26199 / 1906 | |

| 2.3 | Încărcare pe axe fără sarcină, față/spate (catarg simplex, înălțime minimă de ridicare) | kg | 5190 / 5070 | 5190 / 5070 | 5200 / 5230 | 5200 / 5230 | 5240 / 5530 | 5240 / 5530 | 6590 / 5505 | 6590 / 5505 | 6590 / 5505 | 7490 / 6685 | 7120 / 6305 | 7120 / 6305 | 7490 / 6685 | 7660 / 6765 | 8840 / 7265 | |

| Roți, Tren Rulare | ||||||||||||||||||

| 3.1 | Anvelope: V=solide, L=pneumatice, SE=solide pneumatice - față/spate | SE | SE | SE | SE | SE | SE | SE | SE | SE | SE | SE | SE | SE | SE | SE | ||

| 3.2 | Dimensiunile anvelopelor, față | 8.25–15 | 8.25–15 | 8.25–15 | 8.25–15 | 8.25–15 | 8.25–15 | 8.25–15 | 8.25–15 | 8.25–15 | 8.25–15 | 8.25–15 | 8.25–15 | 300–15 | 300 - 15 | 355 / 65–15 | ||

| 3.3 | Dimensiunile anvelopelor, spate | 22x9-16 23x10-12 | 22x9-16 23x10-12 | 22x9-16 23x10-12 | 22x9-16 23x10-12 | 22x9-16 23x10-12 | 22x9-16 23x10-12 | 22x9-16 23x10-12 | 315 / 45–12 | 22 ×9–16 23 ×10–12 | 315 / 45–12 | 23 ×10–12 | 23 ×10–12 | 315 / 45–12 | 315 / 45–12 | 315 / 45–12 | ||

| 3.5 | Numărul de roți, față/spate (x=motoare) | 2 ×/2 | 2 ×/2 | 2 x/2 | 2 ×/2 | 2 ×/2 | 2 ×/2 | 2 ×/2 | 4 ×/2 | 2 ×/2 | 4 ×/2 | 4 ×/2 | 4 ×/2 | 4 ×/2 | 4 ×/2 | 4 ×/2 | ||

| 3.6 | Lățimea ecartamentului (centrul roților), partea de tracțiune | b10 | mm | 1305 1375 1380 | 1306 1375 1380 | 1307 1375 1380 | 1308 1375 1380 | 1309 1375 1380 | 1310 1375 1380 | 1311 1375 1380 | 1460 | 1312 1375 1380 | 1460 | 1380 | 1380 | 1460 | 1460 | 1565 |

| 3.7 | Lățimea ecartamentului (centrul roților), partea de încărcare | b11 | mm | 1220 1225 | 1221 1225 | 1222 1225 | 1223 1225 | 1224 1225 | 1225 1225 | 1226 1225 | 1215 | 1227 1225 | 1215 | 1225 | 1225 | 1215 | 1215 | 1215 |

| Dimensiuni | ||||||||||||||||||

| 4.1 | Înclinare catarg, înainte/înapoi | a / b | ° | 5.5/6(2) | 5.5/6(2) | 5.5/6(2) | 5.5/6(2) | 5.5/6(2) | 5.5 / 6(2) | 5.5 / 6(2) | 5.5/6(2) | 5.5/6(2) | 5.5/6(2) | 5.5/6(2) | 5.5/6(2) | 5.5/6(2) | 5.5/6(2) | 5.5/6(2) |

| 4.2 | Înălțime cu catargul coborât (vezi tabelele) | h1 | mm | 2680 | 2680 | 2680 | 2680 | 2680 | 2680 | 2792 | 2900 | 2792 | 2900 | 2900 | 2900 | 2950 | 2950 | 2950 |

| 4.3 | Ridicare liberă (vezi tabele) | h2 | mm | 100 | 100 | 100 | 100 | 100 | 100 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 4.4 | Înălțimea de ridicare (vezi tabelele) | h3 | mm | 3400 | 3400 | 3400 | 3400 | 3400 | 3400 | 3400 | 3400 | 3400 | 3400 | 3400 | 3400 | 3400 | 3400 | 3400 |

| 4.5 | Înălțime cu catargul extins | h4 | mm | 4370 | 4370 | 4370 | 4370 | 4370 | 4370 | 4530 | 4800 | 4530 | 4800 | 4800 | 4800 | 4850 | 4850 | 4900 |

| 4.7 | Înălțimea până la partea superioară a protecției deasupra capului | h6 | mm | 2420 | 2420 | 2420 | 2420 | 2420 | 2420 | 2420 | 2420 | 2420 | 2420 | 2420 | 2420 | 2420 | 2420 | 2420 |

| 4.8 | Înălțime scaun | h7 | mm | 1330 | 1330 | 1330 | 1330 | 1330 | 1330 | 1330 | 1330 | 1330 | 1330 | 1330 | 1330 | 1330 | 1330 | 1330 |

| 4.12 | Înălţimea la cârligul de remorcare | h10 | mm | 465 | 465 | 465 | 465 | 465 | 465 | 465 | 465 | 465 | 465 | 465 | 465 | 465 | 465 | 465 |

| 4.19 | Lungime totală | l1 | mm | 4550 | 4550 | 4550 | 4550 | 4550 | 4550 | 4840 | 5340 | 4840 | 5340 | 4880 | 4880 | 4960 | 4960 | 5325 |

| 4.20 | Lungimea până la suprafața furcii (inclusiv grosimea furcii) | l2 | mm | 3300 | 3300 | 3300 | 3300 | 3300 | 3300 | 3640 | 3740 | 3640 | 3740 | 3680 | 3680 | 3760 | 3760 | 4125 |

| 4.21 | Lăţime de gabarit | b1/b2 | mm | 1660 / 1830 | 1661 / 1830 | 1662 / 1830 | 1663 / 1830 | 1664 / 1830 | 1665 / 1830 | 1666 / 1830 | 1900 | 1667 / 1830 | 1900 | 1830 | 1830 | 2000 | 2000 | 2140 |

| 4.22 | Dimensiunile furcii (grosime, lățime, lungime) | s,e,l | mm | 150 × 60 × 1200 | 150 × 60 × 1200 | 150 × 60 × 1200 | 150 × 60 × 1200 | 150 × 60 × 1200 | 150 × 60 × 1200 | 200 × 60 × 1200 | 200 × 60 ×1200 | 200 × 60 ×1200 | 200 × 70 ×1600 | 200 × 60 ×1200 | 200 × 60 ×1200 | 200 × 60 ×1200 | 200 × 60 ×1200 | 200 × 70 ×1200 |

| 4.23 | Suport furcă conform DIN 15 173 A/B/nr | 4A | 4A | 4A | 4A | 4A | 4A | 4A | 4A | 4A | 4A | 5A | 5A | 5A | 5A | HD12) | ||

| 4.24 | Lățimea suportului furcii | b3 | mm | 1300 | 1300 | 1300 | 1300 | 1300 | 1300 | 1300 | 1800 | 1300 | 1800 | 1500 | 1500 | 1800 | 1800 | 2000 |

| 4.31 | Garda la sol sub catarg, cu încărcare | m1 | mm | 180 | 180 | 180 | 180 | 180 | 180 | 180 | 180 | 180 | 180 | 180 | 180 | 180 | 180 | 180 |

| 4.32 | Garda la sol în centrul ampatamentului, cu sarcină (furci coborâte) | m2 | mm | 165 | 165 | 165 | 165 | 165 | 165 | 165 | 165 | 165 | 165 | 165 | 165 | 165 | 165 | 165 |

| 4.33 | Lățimea culoarului de lucru cu paleți 1000 × 1200 mm, în cruce | Ast | mm | 4835 | 4610 | 4835 | 4610 | 4835 | 4610 | 5200 | 5350 | 4955 | 4955 | 5220 | 4975 | 5420 | 5420 | 5705 |

| 4.34b | Lățimea culoarului de lucru (Ast3) cu paleți de 800 × 1200 mm, încărcare pe lungime, platformă sus/jos | Ast3 | mm | 5035 | 4745 | 5035 | 4745 | 5035 | 4745 | 5400 | 5550 | 5095 | 5095 | 5420 | 5115 | 5420 | 5420 | 5905 |

| 4.35 | Raza cercului de rotație | Wa | mm | 2985 | 2650 | 2985 | 2650 | 2985 | 2650 | 3300 | 3450 | 2950 | 2950 | 3300 | 2950 | 3500 | 3500 | 3705 |

| 4.36 | Distanța minimă dintre centrele de rotație | b13 | mm | 950 | - | 950 | - | 950 | - | 1050 | 1050 | - | 1150 | 1050 | 1050 | 1250 | 1250 | 1250 |

| Performanţă | ||||||||||||||||||

| 5.1 | Viteza de deplasare, cu/fară încărcatură | km/h | 15 / 15 | 20 / 20 | 15 / 15 | 20 / 20 | 14.5 / 15 | 20 / 20 | 14 / 15 | 14 / 15 | 19 / 20 | 17 / 18 | 15 / 18 | 18 / 19 | 14 / 15 | 16 / 18 | 16 / 17 | |

| 5.2 | Viteza de ridicare, cu/fară încărcatură | m/s | 0.24 / 0.39 | 0.24 / 0.40 | 0.24 / 0.41 | 0.24 / 0.42 | 0.22 / 0.39 | 0.22 / 0.39 | 0.2 / 0.34 | 0.21 / 0.3 | 0.2 / 0.35 | 0.3 / 0.44 | 0.28 / 0.4 | 0.28 / 0.4 | 0.18 / 0.27 | 0.22 / 032 | 0.28 / 0.36 | |

| 5.3 | Viteza de coborâre, cu/fară încărcatură | m/s | 0.5 / 0.4 | 0.39 / 0.45 | 0.5 / 0.6 | 0.37 / 0.45 | 0.5 / 0.8 | 0.35 / 0.45 | 0.45 / 0.35 | 0.45 / 0.37 | 0.31 / 0.45 | 0.5 / 0.4 | 0.47 / 0.39 | 0.28 / 0.4 | 0.5 /0.4 | 0.5 / 0.4 | 0.47 / 0.38 | |

| 5.5 | Tragere nominală a barei de tracțiune, cu/fără sarcină | N | 6900 / 7500 | 6900 / 7500 | 6900 / 7500 | 6900 / 7500 | 6600 / 7300 | 6600 / 7300 | 6400 / 7200 | 5600 / 6300 | 6400 / 7200 | 5600 / 6300 | 6100 / 6850 | 6100 / 6850 | 5000 / 5600 | 5000 / 5650 | 5400 / 6800 | |

| 5.6 | Tracțiune maximă la bara de remorcare, cu/fără încărcatură (5 min de funcționare scurtă) | 16400 / 17000 | 23800 / 24400 | 16400 / 17000 | 23700 / 24300 | 16100 / 16800 | 23600 / 24300 | 15900 / 16700 | 20700 / 21500 | 23300 / 24400 | 20700 / 21500 | 15150 / 15900 | 23000 / 23900 | 18500 / 19000 | 18600 / 19350 | 22900 / 23700 | ||

| 5.7 | Gradulabilitate, cu/fără încărcatură | % | 6.5 / 11 | 8.2 / 13.5 | 6.5 / 11 | 7.9 / 12.8 | 5.5 / 10 | 7.4 / 12.8 | 5 / 9.5 | 5 / 9.5 | 6.4 / 11.1 | 5 / 9 | 4.7 / 9 | 5.6 / 10 | 4 / 8 | 4.5 / 8 | 4.8 / 8.8 | |

| 5.8 | Gradabilitate maximă de înclinare, cu/fără încărcatură | s | 10 / 16 | 14.7 / 23.7 | 10 / 16 | 14.2 / 22.5 | 8.5 / 14 | 13.4 / 22.5 | 8 / 13.5 | 9 / 15 | 11.6 / 19.6 | 9.2 / 16 | 7.7 / 12.7 | 10.3 / 17.8 | 8 / 14 | 8.3 / 14.5 | 8.7/15 | |

| 5.9 | Timp de accelerație (10 metri) cu/fără încărcatură | s | 5.8 / 5.4 | 6.6 / 5.3 | 5.8 / 5.4 | 6.6 / 5.3 | 6.1 / 5.7 | 7 / 5.5 | 6.2 / 5.8 | 6.5 / 5 | 7.4 / 5.6 | 7 / 5.2 | 5.8 / 5.4 | 7.8 / 5.8 | 6 / 4 | 6.2 / 4.7 | 9.6 / 6.9 | |

| 5.10 | Frâne de serviciu (mecanice/hidraulice/electrice/pneumatice) | Electric | Hydraulic / Electric | Electric | Hydraulic / Electric | Electric | Hydraulic / Electric | Electric | Hydraulic / Electric | Hydraulic / Electric | Electric | Electric | Hydraulic / Electric | Hydraulic / Electric | Electric | Electric | ||

| Motoare electrice | ||||||||||||||||||

| 6.1 | Putere motor tracţiune (regim de lucru scurt de 60 min) | kW | 2x15 | 2x15 | 2x15 | 2x15 | 2x15 | 2x15 | 2x15 | 2 ×15 | 2 ×15 | 2 ×15 | 2 ×15 | 2 ×15 | 2 ×15 | 2 ×15 | 2 ×15 | |

| 6.2 | Ieșirea motorului de ridicare la un factor de funcționare de 15%. | kW | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 | |

| 6.3 | Baterie conform DIN 43 531/35/36 A/B/C/nr | - | - | - | - | - | - | - | ||||||||||

| 6.4 | Tensiune/capacitate baterie la 5 ore de descărcare | V/Ah | 96 | 96 | 96 | 96 | 96 | 96 | 96 | 96 | 96 | 96 | 96 | 96 | 96 | 96 | 96 | |

| 6.5 | Greutatea bateriei | kg | 3350 | 3350 | 3350 | 3350 | 3350 | 3350 | 4300 | 4300 | 4300 | 4300 | 4300 | 4300 | 4300 | 4300 | ||

| 6.6a | Consumul de energie conform DIN EN 16796 | kWh/h | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | |

| 6.6b | Consumul de energie conform ciclului VDI 60 | kWh/h | - | - | - | - | - | - | - | |||||||||

| Diverse | ||||||||||||||||||

| 8.1 | Tipul de comandă | Invertor | Invertor | Invertor | Invertor | Invertor | Invertor | Invertor | Invertor | Invertor | Invertor | Invertor | Invertor | Invertor | Invertor | Invertor | ||

| 10.1 | Presiunea de operare pentru accesorii | bar | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | |

| 10.2 | Volumul de ulei pentru atașamente | L/min | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | |

| 10.7 | Nivelul presiunii sonore la scaunul șoferului | dB (A) | 72 | 72 | 72 | 72 | 72 | 72 | 72 | 72 | 72 | 72 | 72 | 72 | 72 | 72 | 72 |