UTILIZAȚI PUTEREA...

MAXIMIZAȚI-VĂ POTENȚIALUL

Când vine vorba de puterea de tracțiune, nimic nu se compară cu gama noastră de stivuitoare de tractare VANTiA. Puternic, dar super inteligent și precis, este tractorul de remorcare de care aveți nevoie pentru a face treaba... oriunde și oricare ar fi acea lucrare.

Puternic, curat și absolut versatil, Echipamentul de tractare VANTiA este la fel de potrivit pentru o fabrică de mare intensitate, precum și pentru cele care necesită curățenie.

Modelele noastre de 3,0 și 5,0 tone sunt dotate cu funcții inteligente, cum ar fi tehnologia noastră SDS extrem de intuitivă. În mod unic, adaptează performanța stivuitorului cu cea a șoferului pentru o productivitate armonioasă.

Echipamentul de tractare VANTiA este disponibil cu o varietate de soluții de cuplare versatile pentru manipularea fără efort a remorcii.

| Model | Capacitate de încărcare |

|---|---|

| TBR30N2 | 3000 kg |

| TBR50N2 | 5000 kg |

Deoarece VANTiA este cu 14% mai eficient decât cel mai apropiat concurent al său, vă permite să lucrați cât mai ușor posibil.

O manevrabilitate excepțională este oferită de unghiul de virare de 100 de grade al VANTiA, de direcția receptivă și de șasiul compact.

Păstrând toate comenzile de operare la îndemână, Maxius oferă cea mai bună ergonomie, confort și design: reducerea riscului de oboseală a brațului și creșterea productivității.

Sistemul Sensitive Drive de la VANTiA adaptează comportamentul stivuitorului în funcție de operatorul și aplicația dvs. pentru operațiuni care sunt în mod constant mai ușoare, mai stabile și mai sigure.

Pentru a spori siguranța și productivitatea operatorului dvs., VANTiA beneficiază de reducerea automată a vitezei în curbe și centrarea automată a roților motoare.

Pe lângă faptul că este certificat pentru siguranță, VANTiA reduce și costurile de service.

Prin reducerea timpului necesar pentru accelerare, VANTiA maximizează productivitatea operatorului.

Podea flotantă cu suspensie triplă a VANTiA, cu amortizare laterală și amortizare avansată, menține microvibrațiile la minimum pentru un confort remarcabil al operatorului.

Garda la sol excepțională a VANTiA de până la 220 mm asigură că operațiunile cu rampă și docul de încărcare sunt ușoare, sigure și eficiente.

Permite operatorului să se întoarcă pentru o vedere mai bună atunci când manevrează în marșarier.

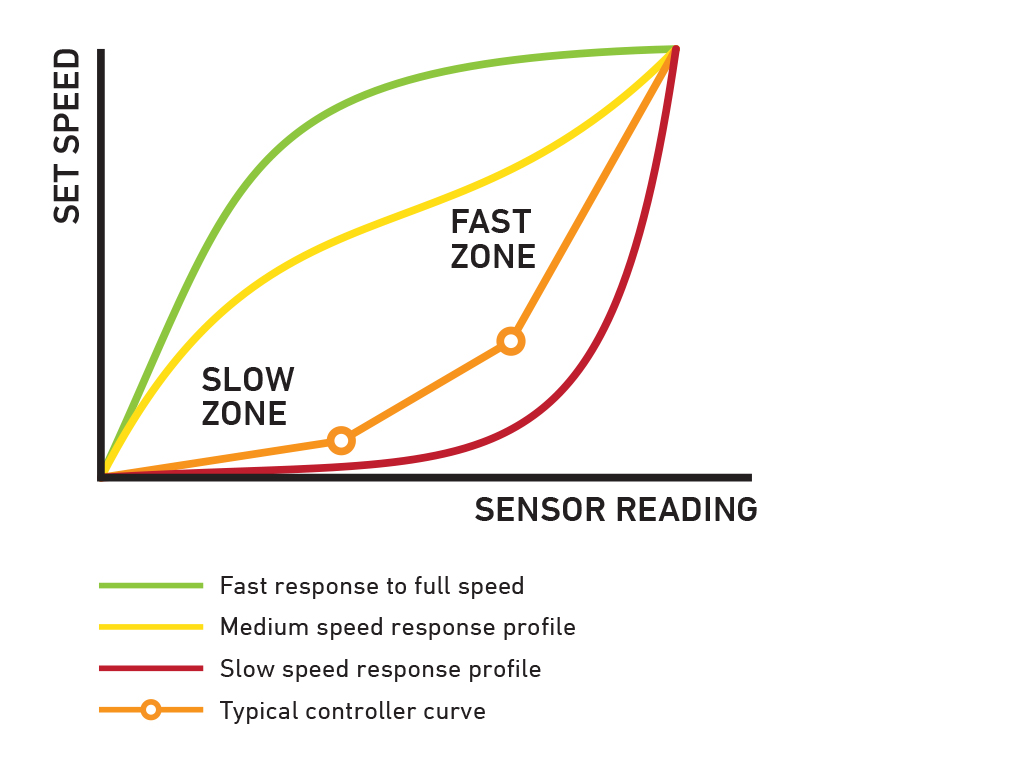

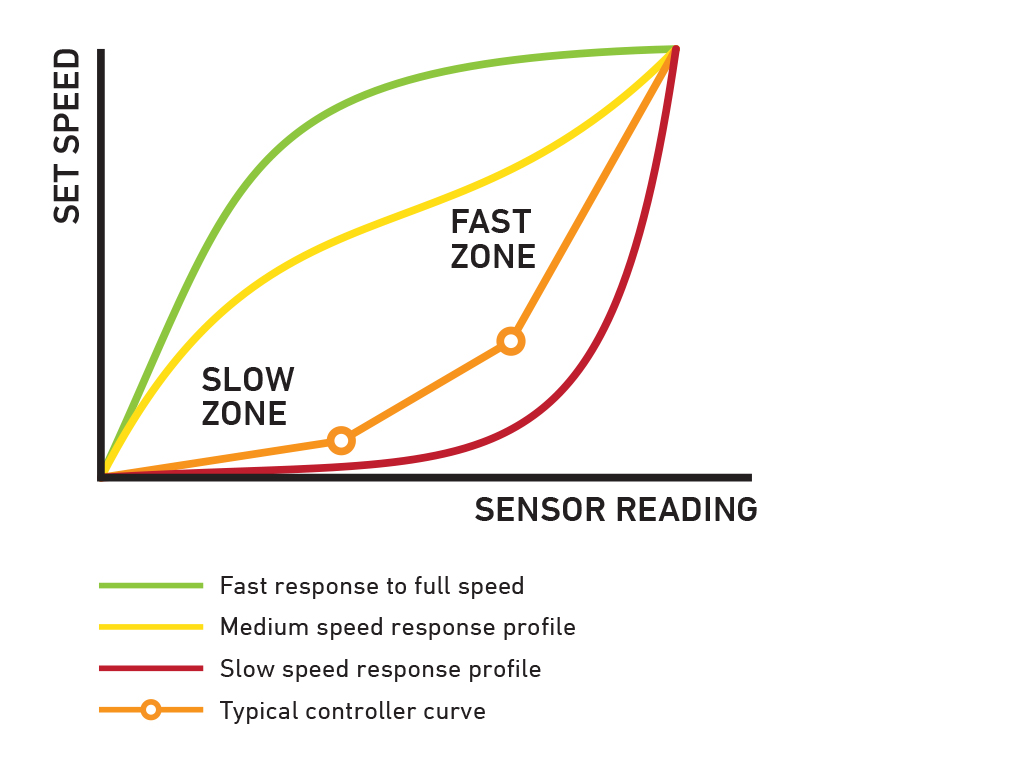

Sistem de acționare sensibil (SDS)

Detectează mișcările de control ale operatorului mai rapide sau mai lente și ajustează performanța stivuitorului în consecință, contribuind la siguranța și la performanța șoferului.

Volan Maxius de următoarea generație

Absoarbe vibrațiile și șocurile pentru a asigura o ergonomie de vârf în clasă.

Cerc de întoarcere mic

Împreună cu direcția receptivă și șasiul compact rezultă o manevrabilitate excepțională.

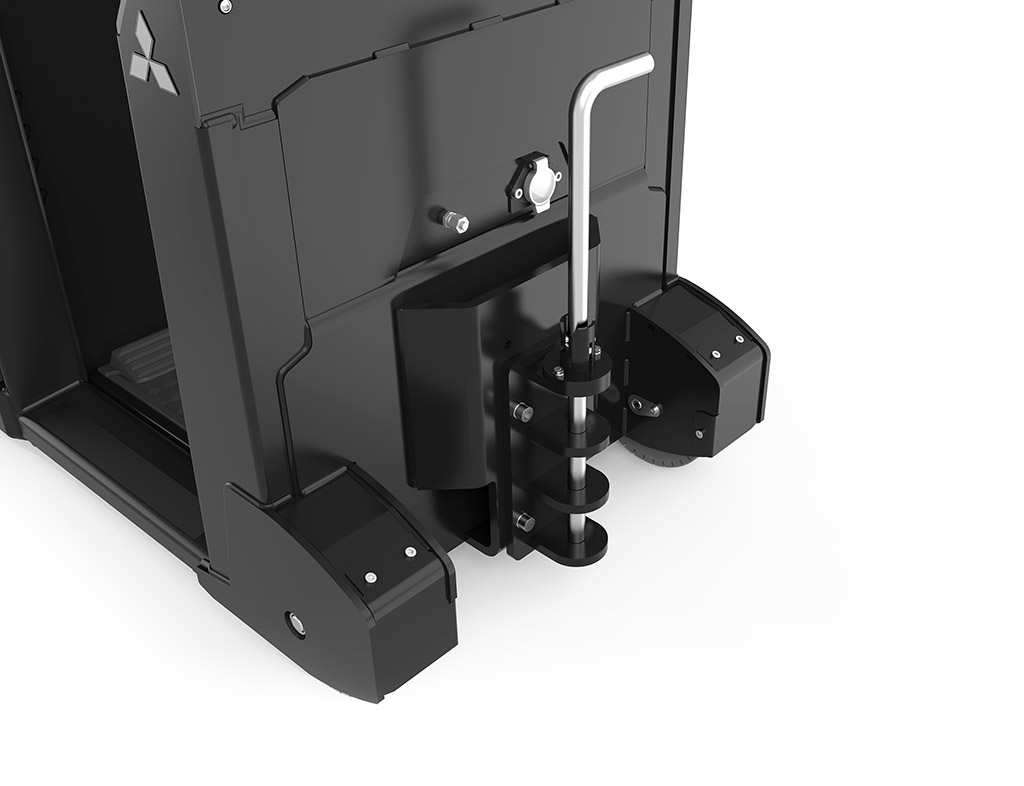

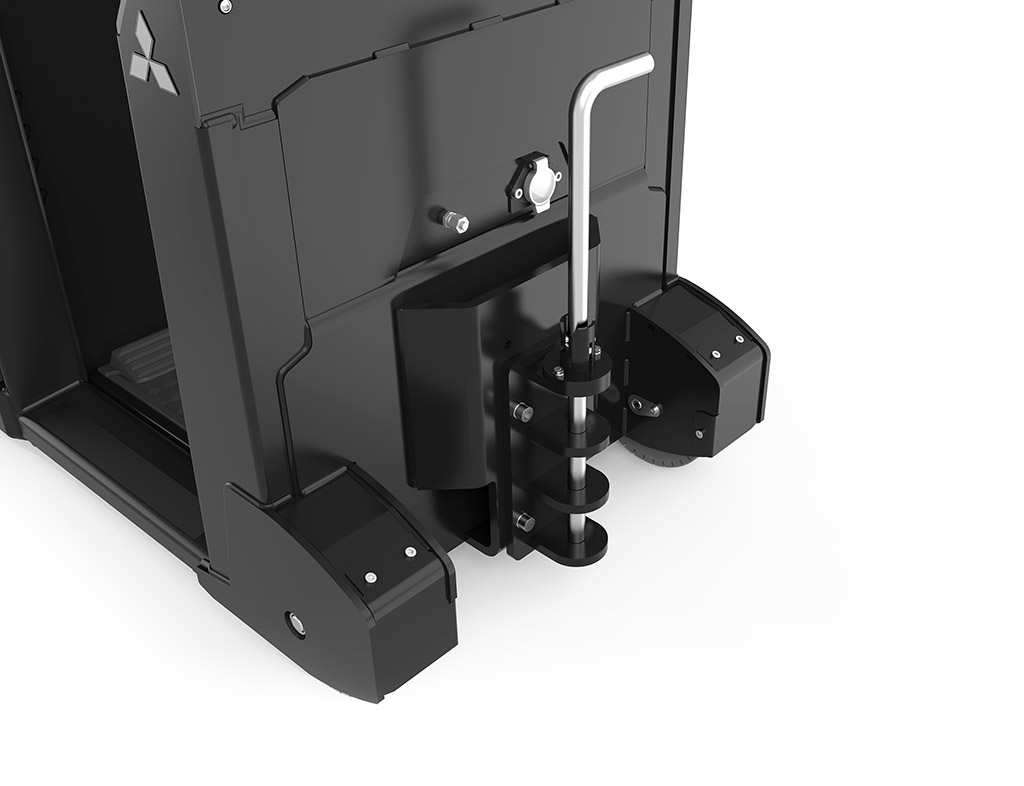

Cuplaj manual de remorcare

cu pin versatil și reglabil pentru manipularea rapidă și ușoară a remorcii.

Eficiență energetică de top

(cu 14% mai mic decât cel mai apropiat concurent) asigură că, costurile de funcționare sunt menținute la minimum.

Tehnologia Flying Start

Scurtează timpul de accelerare pentru o productivitate maximă la picking.

Platformă ușor de accesat

prezintă înălțime mică a treptei și margini teșite - minimizând pericolele de împiedicare pentru un acces ușor de intrare/ieșire.

Interval de service de 600 de ore

Reduce timpul de nefuncționare și costurile de service.

Cuplaj automat de remorcare (opțional)

Blochează imediat stivuitorul și remorca odată ce sunt poziționate, în timp ce o opțiune suplimentară de decuplare manuală permite eliberarea fără a părăsi compartimentul operatorului.

Pentru a profita la maximum de la operator și mașină, sistemul nostru centralizat pentru controlul AC utilizează un control inteligent avansat, plus cea mai recentă tehnologie MOSFET și disipare a căldurii pentru performanță maximă și eficiență energetică.

Oferind o putere mare pentru o tracțiune și o performanță excelentă pe rampă, oferă o funcționare lină, silențioasă și controlată, durate extinse ale schimburilor și cerințe reduse de întreținere.

Revoluționarul SDS (Sistem de Conducere Sensibil) folosește un software revoluționar care permite stivuitorului să simtă - de la prima atingere - exact cum dorește un șofer să opereze.

Performanța este gestionată în funcție de unghiul de virare și de viteza comenzilor cu picior și degete.

Inspirat de Formula 1, acest design ergonomic premiat aduce toate comenzile de operare la îndemână cu ambele mâini.

Oferind cel mai bun confort și design, poate fi ajustat pentru a se potrivi poziției ideale a fiecărui șofer și poate fi operat cu ușurință cu o singură mână.

Încercate, testate și dovedite în domeniu, bateriile plumb-acid au fost alegerea de lungă durată pentru companiile care folosesc stivuitoare electrice. Cu toate acestea, cu timpi lungi de încărcare, cerințe solicitante de întreținere, nevoia de baterii suplimentare și riscul ridicat de utilizare greșită de către operator, poate fi o provocare. Din fericire, există un nou sistem de baterii pe bloc: Li-ion de la Mitsubishi Forklift Trucks.

Conceput pentru a satisface cerințele afacerii dvs. - inclusiv operațiuni în mai multe schimburi (24/7) - fără a fi nevoie de baterii de rezervă, sistemul nostru de baterii Li-ion de înaltă performanță este cu până la 40% mai eficient decât omologii plumb-acid. În plus, este practic rezistent la erori, datorită designului său cu întreținere foarte redusă, care previne deteriorarea celulelor.

Eficiență excepțională, cu zero emisii

Cu 40% mai eficiente decât bateriile plumb-acid și fără gaze.

Design cu întreținere ultra-scăzută

Doar o încărcare completă în fiecare săptămână pentru a activa echilibrarea celulelor, precum și un export/actualizare CSV anual.

Nu este necesar spațiu

Fără a fi nevoie de zone de încărcare, nu există costuri de instalare și vă puteți păstra spațiul profitabil.

Capabilitati de încărcare rapidă

Doar 15 minute este tot ceea ce are nevoie bateria pentru ca stivuitorul să funcționeze încă câteva ore. (Este nevoie de doar 1 până la 2 ore pentru a încărca complet o baterie complet descărcată.)

Tensiune susținută mai mare

Acest lucru asigură o performanță mai consistentă la ridicare și la conducere, care este deosebit de vizibilă spre sfârșitul unui schimb.

Tehnologia TriCOM

Ajută la furnizarea unei eficiențe excepțional de ridicate a sistemului (până la 97%)

| Caracteristici | |||||

| 1.7 | Forţa de tracţiune nominală la cârlig | F | N | 600 | 1000 |

| 1.2 | Denumirea modelului producătorului | TBR30N2 | TBR50N2 | ||

| 1.3 | Sursa de alimentare: (baterie, motorină, gaz LP, benzină) | Baterii | Baterii | ||

| 1.4 | Modul de operare: pieton, (operator)-în picioare, -așezat | Stand-on | Stand-on | ||

| 1.5 | Capacitate de încărcare | Q | kg | 3000 | 5000 |

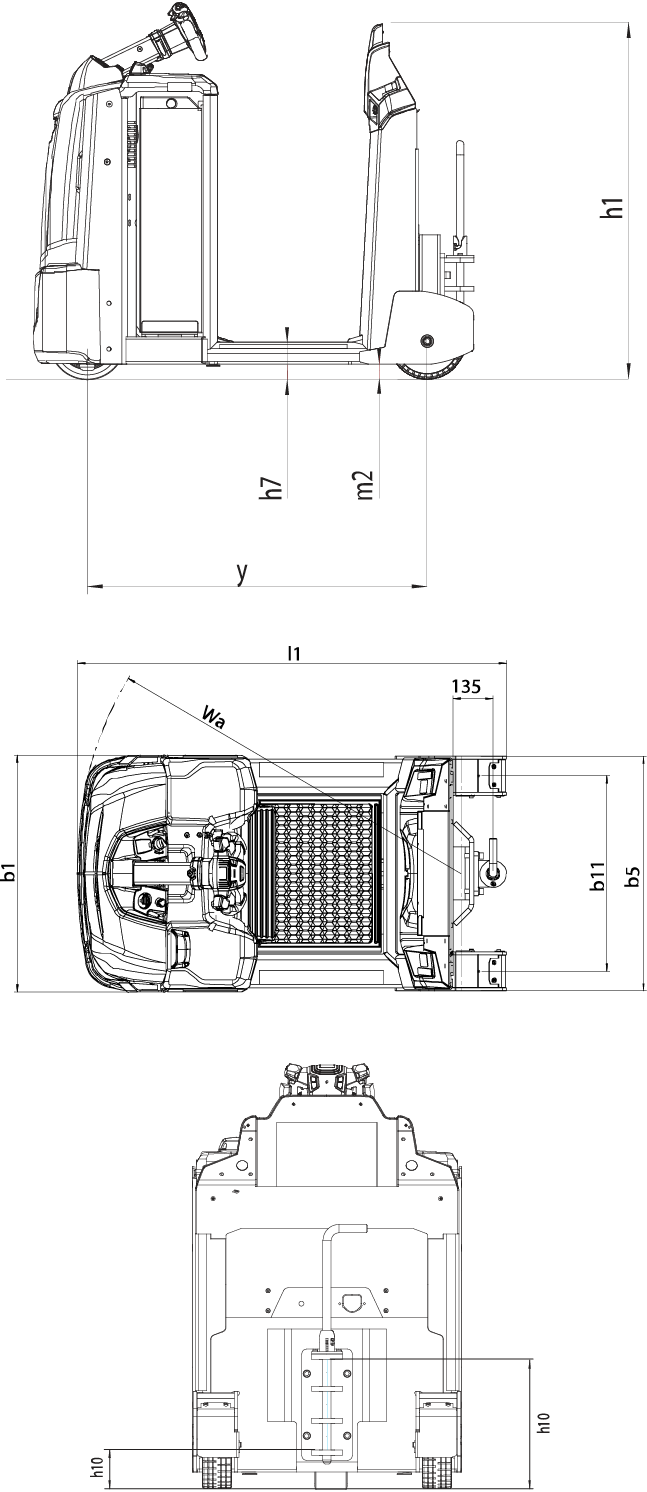

| 1.9 | Ampatament | y | mm | 1120 3) | 1120 3) |

| Greutate | |||||

| 2.1 | Masă utilaj fără încărcătură, baterie cu masă maximă | kg | 1106 | 1106 | |

| 2.3 | Încărcare pe axe fără sarcină, față/spate (catarg simplex, înălțime minimă de ridicare) | kg | 616 / 490 | 616 / 490 | |

| Roți, Tren Rulare | |||||

| 3.1 | Tip roată : PT=Power Thane, Vul=Vulkollan, P=Poliuretan, N=Nailon, C=Cauciuc faţă/spate | Vul / Vul | Vul / Vul | ||

| 3.2 | Dimensiuni roată, faţă | ø250 | ø250 | ||

| 3.3 | Dimensiuni roată, spate | ø250 | ø250 | ||

| 3.5 | Număr de roţi, spate/faţă (x=motoare) | 2 / 1x | 2 / 1x | ||

| 3.7 | Ecartament (centrul rotilor), partea de comandă | b11 | mm | 650 | 650 |

| Dimensiuni | |||||

| 4.2 | Înălţime | h1 | mm | 1173 | 1173 |

| 4.8 | Seat height | h7 | mm | 123 | 123 |

| 4.12 | Înălţimea postului de lucru | h10 | mm | 155 1) | 155 1) |

| 4.19 | Lungimea totală | l1 | mm | 1450 3) | 1450 3) |

| 4.21 | Lăţime de gabarit | b1/b2 | mm | 800 | 800 |

| 4.25 | Lăţime exterioară deasupra furcilor (minim/maxim) | b5 | mm | 794 | 794 |

| 4.32 | Garda la sol la mijlocul ampatamentului, cu sarcină (furcile coborâte) | m2 | mm | 50 | 50 |

| 4.35 | Rază de virare | Wa | mm | 1306 3) | 1306 3) |

| Performanţă | |||||

| 5.1 | Viteza de deplasare, cu/fără sarcină | km/h | 9.0 / 13.0 2) | 7.0 / 13.0 2) | |

| 5.7 | Pantă admisibilă, cu/fără sarcină | % | 6 / 15 | 4 / 15 | |

| 5.10 | Frâne de serviciu (mecanice/hidraulice/electrice/pneumatice) | Electric | Electric | ||

| Motoare electrice | |||||

| 6.1 | Putere motor tracţiune (regim de lucru scurt de 60 min) | kW | 2.6 | 2.6 | |

| 6.4 | Baterie, tensiune/capacitate - 5 ore de funcţionare | V/Ah | 24 / 465-620 | 24 / 465-620 | |

| 6.5 | Greutatea bateriei | kg | 355-493 | 355-493 | |

| 6.6 | Consumul de energie conform ciclului VDI 60 | kWh/h | 0.92 | 1.23 | |

| Diverse | |||||

| 8.1 | Tipul de comandă | Stepless | Stepless | ||

| 8.4a | Nivelul de zgomot la nivelul urechii șoferului conform EN 12 053:2001 și EN ISO 4871 în lucru LpAZ | dB(A) | 69 4) | 69 4) | |

| 8.4b | Nivelul de zgomot la nivelul urechii șoferului conform EN 12 053:2001 și EN ISO 487, conducere/ridicare/repaus LpAZ | dB(A) | 73 / - / - 4) | 73 / - / - 4) | |

| 8.6a | Vibrații ale întregului corp (EN 13 059:2002) | m/s² | 0.9 | 0.9 |