Empower your operator...

transform your operations

Despite its ultracompact size, our VELiA ES range of low level order pickers is packed with smart features that will have your operations running more efficiently, productively and reliably. Oh, and safer, too.

At the heart of every VELiA ES model is hyper-intelligent software that moulds the truck's behaviour to your operator and your operations for performance that is consistently easier, steadier and safer.

With drive speeds of up to 13 km/h, VELiA ES is sure to pick up the pace of your operations... whichever model you choose (standard, rising platform [P], rising fork [F] and scissor lift [X]).

| Model | Load Capacity |

|---|---|

| OPB12N2F | 1200 kg |

| OPB12N2FP | 1200 kg |

| OPB20N2 | 2000 kg |

| OPB20N2P | 2000 kg |

| OPB20N2X | 2000 kg |

| OPB20N2XP | 2000 kg |

| OPB25N2 | 2500 kg |

| OPB25N2P | 2500 kg |

Because VELiA ES is 14 per cent more efficient than its nearest competitor, VELiA ES lets you work as leanly as possible.

VELiA's extensive testing, which includes safety certification, enhances safety while lowering service costs.

VELiA ES' Sensitive Drive System moulds the truck's behaviour to your operator's and application's for operations that are consistently easier, steadier and safer.

This option offers 40% greater efficiency than traditional lead acid... and minimises the risk of operator error.

Maxius keeps all controls within easy reach. Its exceptional ergonomics maximise productivity, increase safety and significantly reduce driver arm fatigue.

By reducing the amount of time required for acceleration, VELiA ES operators maximise their picking productivity.

Exceptional manoeuvrability is offered by VELiA ES' 100-degree steering angle, responsive steering and compact chassis.

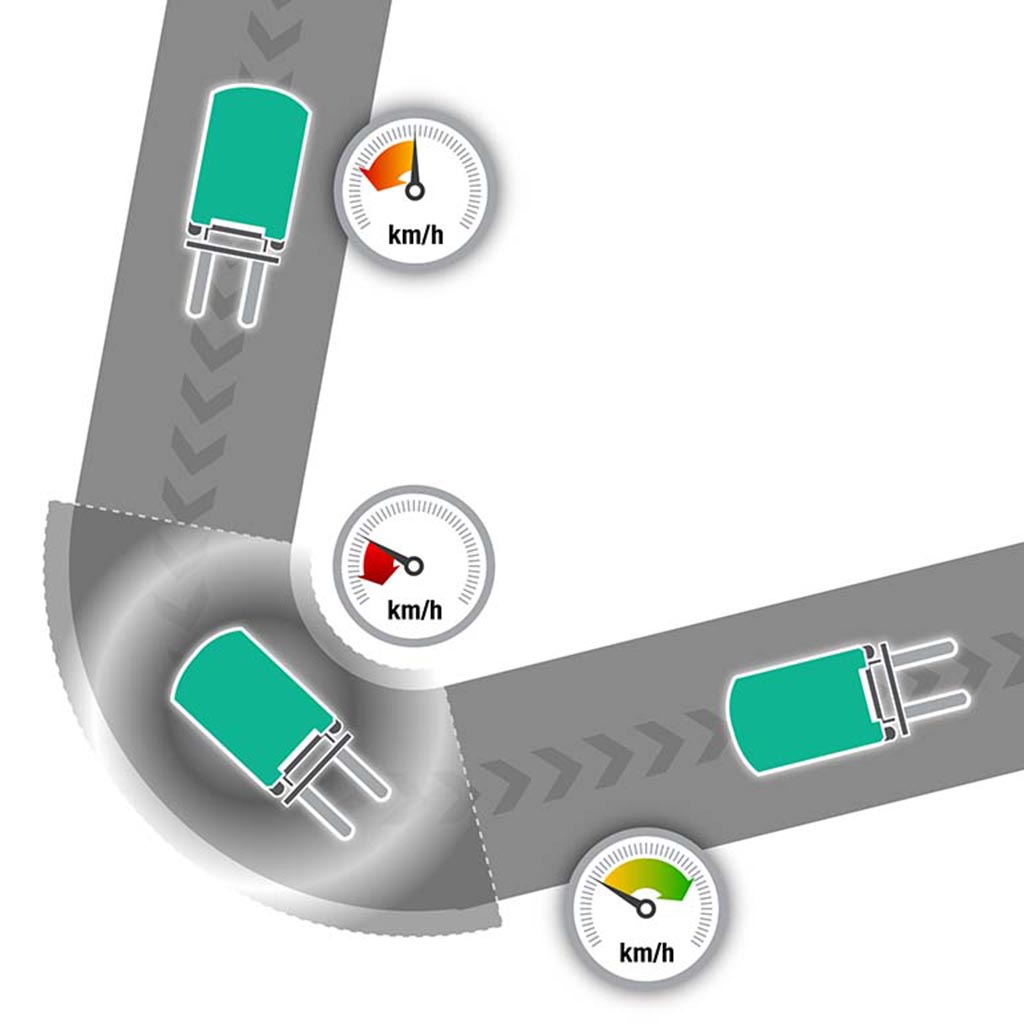

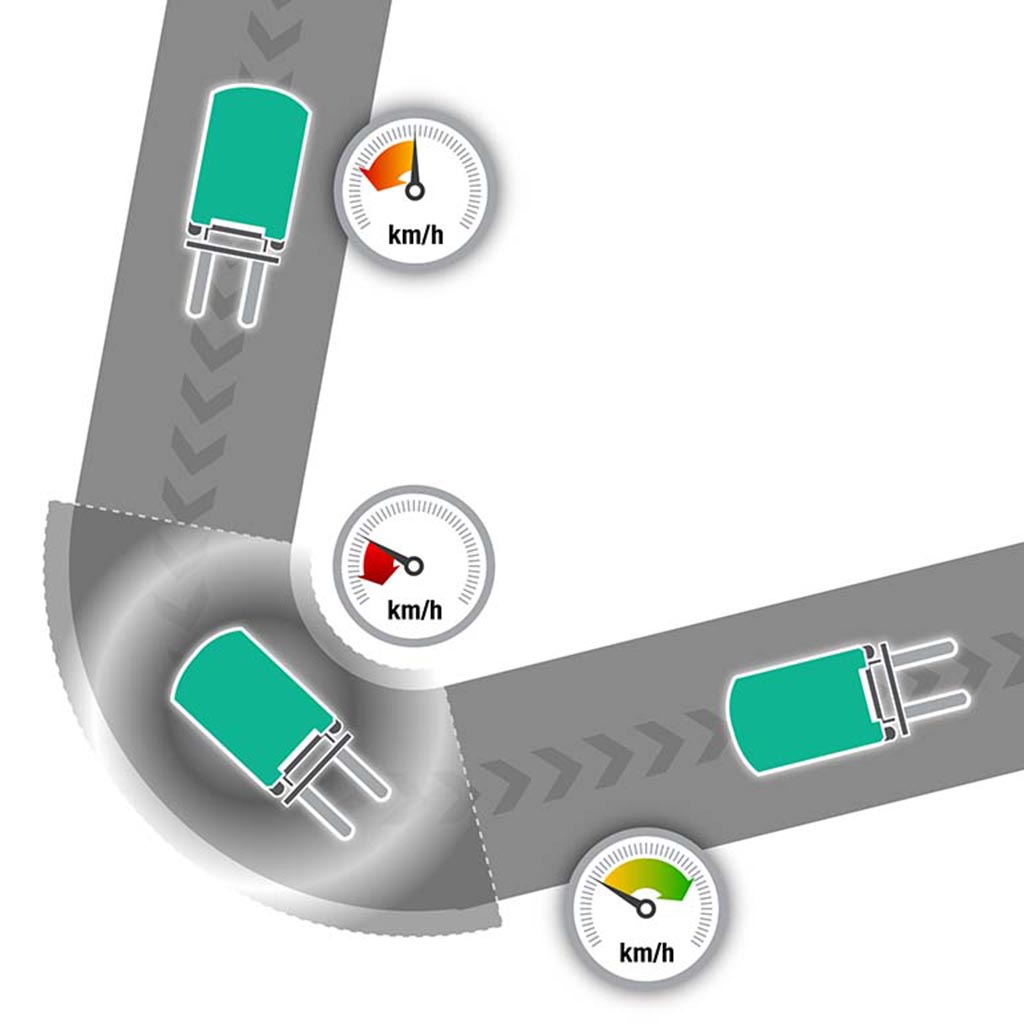

To enhance your operator's safety and productivity, VELiA ES benefits from automatic speed reduction in curves and automatic drive wheel centering.

Together, these allow operators reverse travel - even over long distance - in absolute comfort to keep fatigue at bay.

Covering the whole floor, this eliminates the need for a dead man's switch, a common trip hazard, while allowing operators to move freely and comfortably.

VELiA's exceptional ground clearance of up to 220 mm ensures that ramp and loading dock operations are easy, safe and efficient.

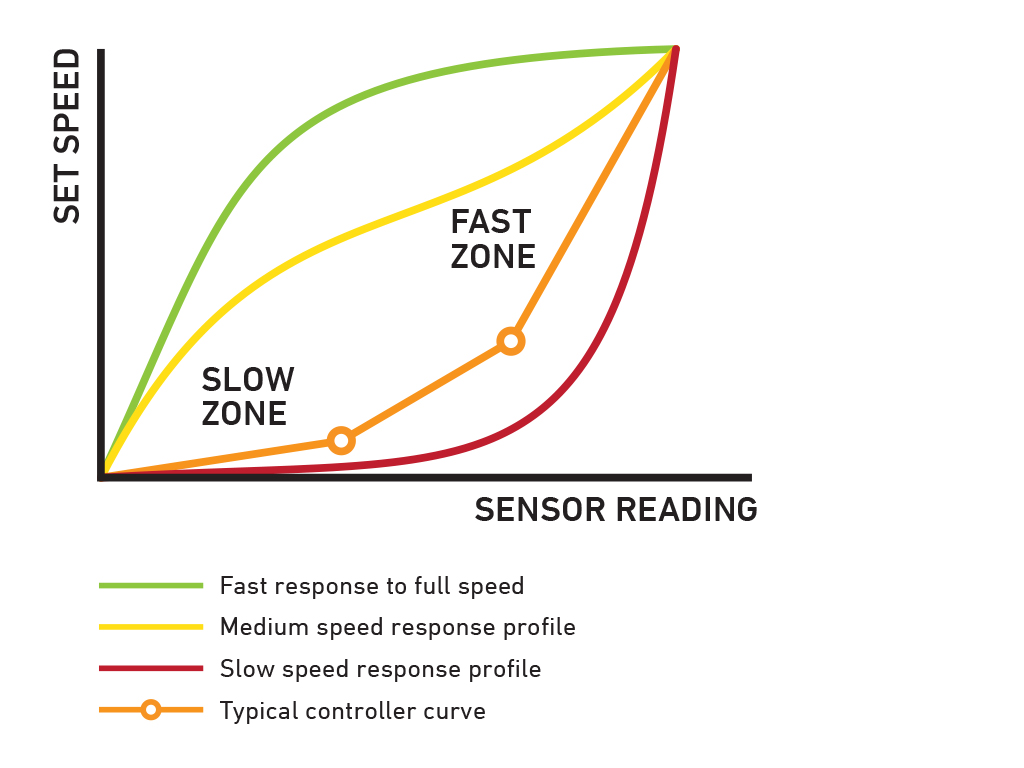

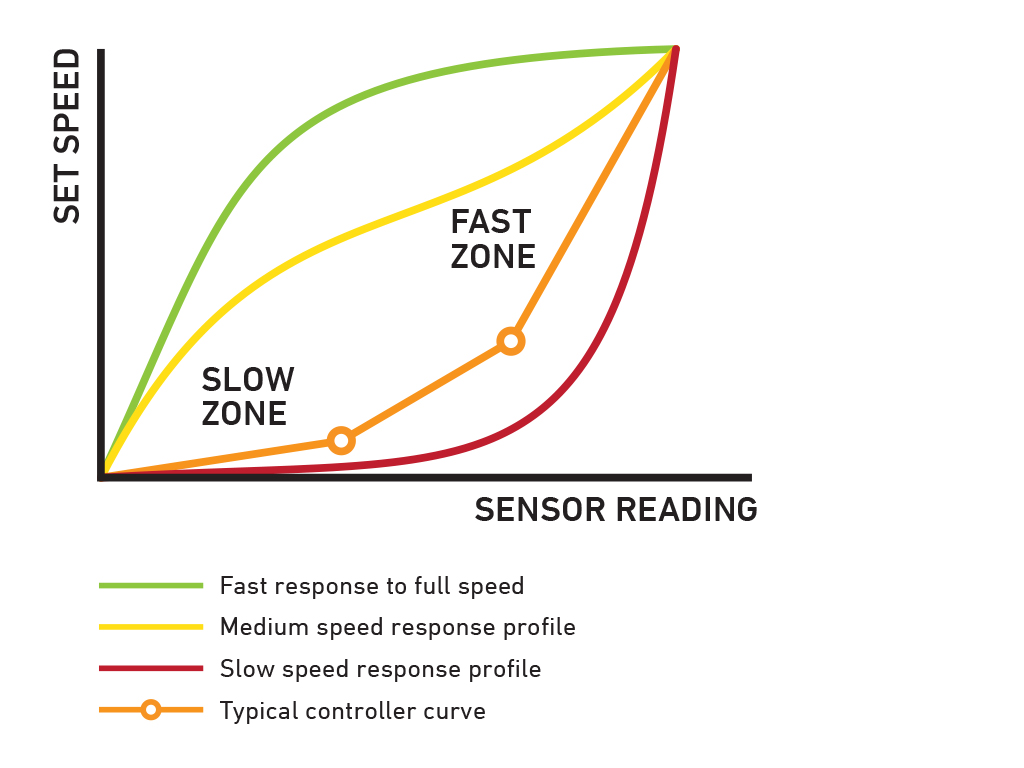

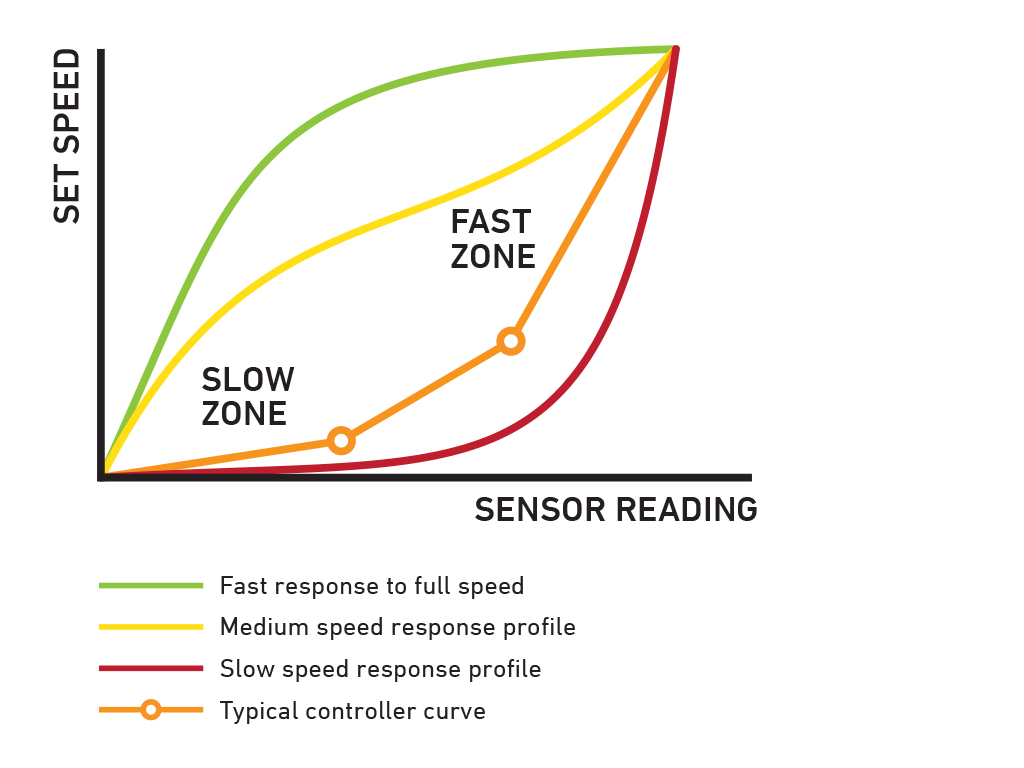

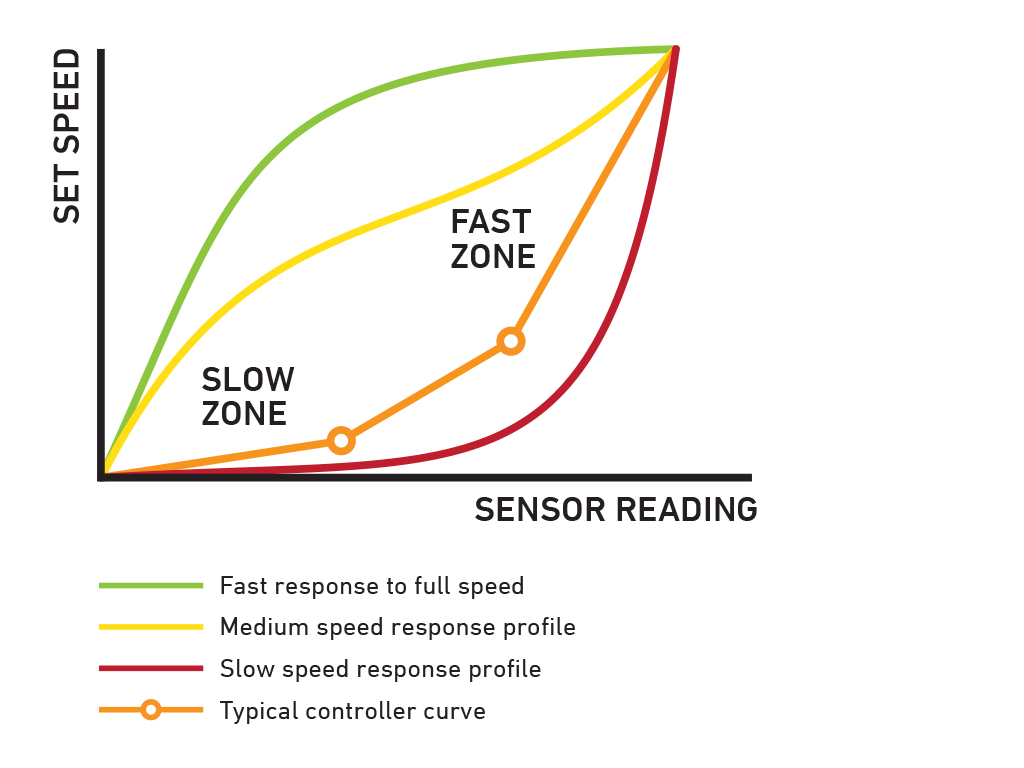

Sensitive Drive System (SDS)

senses faster or slower operator control movements and adjusts truck performance accordingly, contributing to safety and driver performance.

Li-ion battery (option)

allows for fast charging - removing the need for extra batteries.

Intelligent Cornering System

automatically adjusts truck speed according to steer angle for increased operator and site safety, improved productivity and reduced tyre wear.

Flying Start technology

shortens acceleration time for ultimate picking productivity.

Next generation Maxius steering wheel

absorbs vibrations and shocks to ensure class-leading ergonomics.

Sideways standing position

and ergonomic controls ensure operators can travel in reverse, even over long distances, in comfort.

Lift height

up to 220 mm - offers high ground clearance for easy and safe handling on loading docks and ramps.

To get the most from operator and machine our centralised system for AC control uses advanced intelligent control, plus the latest MOSFET and heat dissipation technology for maximum performance and energy efficiency.

Offering high power for excellent traction and ramp performance, it provides smooth, quiet and controlled operation, extended shift lengths and reduced maintenance requirements.

The revolutionary SDS (Sensitive Drive System) employs ground-breaking software that allows the truck to sense - from the very first touch - exactly how a driver wishes to operate.

Performance is managed according to steer angle and the velocity of foot and finger controls.

Inspired by Formula 1, this award-winning ergonomic design brings all operating controls within easy reach of both hands.

Offering the best in comfort and design, it can be adjusted to suit each driver's ideal position and can be easily operated one-handed.

Tried, tested and proven in the field, lead-acid batteries have been the long-standing choice for companies employing electric lift trucks. However, with long charging times, demanding maintenance requirements, the need for extra batteries, and high risk of operator misuse, it can be a challenge. Fortunately, there's a new battery system on the block: Li-ion from Mitsubishi Forklift Trucks.

Designed to meet your business' demands - including multi-shift (24/7) operations - without the need for spare batteries, our high-performance Li-ion battery system is up to 40 per cent more efficient than lead-acid counterparts. Plus, it's virtually error-proof, thanks to its ultra-low-maintenance design which prevent cell damage.

Exceptional, zero-emissions efficiency

40% more efficient than lead-acid batteries and free from gases.

Ultra-low maintenance design

Just a full charge each week to activate cell balancing, as well as an annual CSV export/update.

No space required

With no need for charging areas, there's no cost for set up and you can keep your profitable space just that: profitable.

Quick charge capabilities

Just 15 minutes is all your battery needs to keep your truck going a few more hours. (It only takes 1 to 2 hours to fully charge a completely discharged battery.)

Higher sustained voltage

This ensures more consistent lifting and driving performance, which is particularly noticeable towards the end of a shift.

TriCOM Technology

Helps to deliver exceptionally high system efficiency (up to 97%)

| Characteristics | |||||||||||

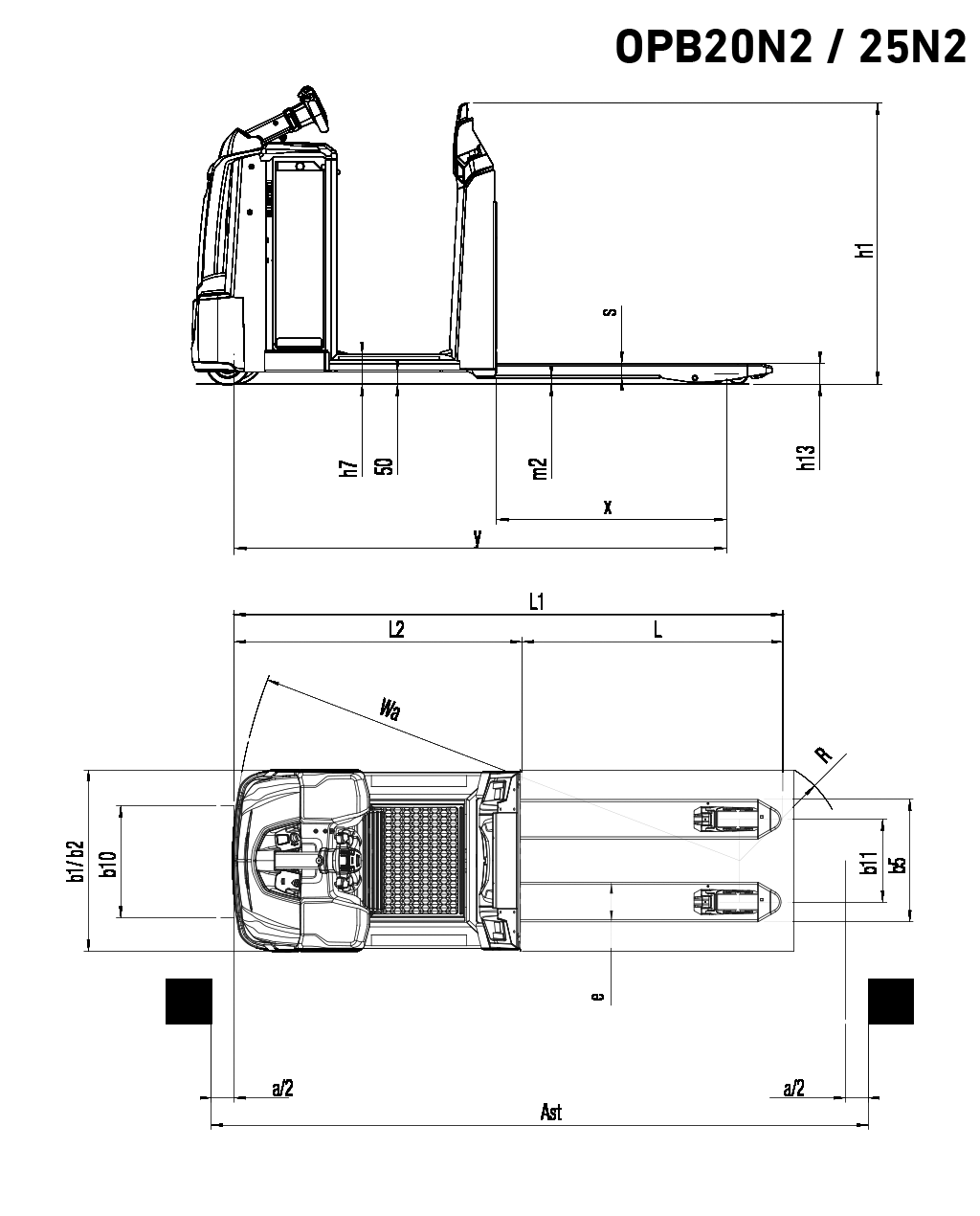

| 1.2 | Manufacturer's model designation | OPB12N2F | OPB12N2FP | OPB20N2 | OPB20N2P | OPB20N2X | OPB20N2XP | OPB25N2 | OPB25N2P | ||

| 1.3 | Power source: (battery, diesel, LP gas, petrol) | Battery | Battery | Battery | Battery | Battery | Battery | Battery | Battery | ||

| 1.4 | Operator type: pedestrian, (operator)-standing, -seated | Stand-on | Stand-on | Stand-on | Stand-on | Stand-on | Stand-on | Stand-on | Stand-on | ||

| 1.5 | Load capacity | Q | kg | 1200 | 1200 | 2000 | 2000 | 2000 | 2000 | 2500 | 2500 |

| 1.6 | Load centre distance | c | mm | 600 | 600 | 600 | 600 | 1200 | 1200 | 600 | 600 |

| 1.8 | Load wheel axle to fork face (forks lowered) | x | mm | 785 | 785 | 960 | 960 | 1480 | 1480 | 960 | 960 |

| 1.9 | Wheelbase | y | mm | 1929 5) | 1929 5) | 2054 5) | 2054 5)) | 2640 5) | 2640 1) | 2054 5) | 2054 1) |

| Weight | |||||||||||

| 2.1 | Truck weight without load, with maximum battery weight | kg | 1220 2) | 1356 2) | 1079 1) | 1215 1) | 1333 1) | 1469 1) | 1079 1) | 1215 1) | |

| 2.2 | Axle loadings with nominal load & maximum battery weight, drive/load side | kg | 972/1448 | 1059/1497 | 1082 / 1997 | 1130 / 2085 | 1135 / 2220 | 1230 / 2261 | 1178 / 2401 | 1223 / 2492 | |

| 2.3 | Axle loadings without load & with maximum battery weight, drive/load side | kg | 853/367 | 940/416 | 829 / 250 | 913 / 302 | 929 / 404 | 1024 / 445 | 829 / 250 | 913 / 302 | |

| Wheels, Drive Train | |||||||||||

| 3.1 | Tyres: PT=Power Thane, Vul=Vulkollan, drive/load side | Vul / Vul | Vul / Vul | Vul/ Vul | Vul/ Vul | Vul/ Vul | Vul/ Vul | Vul/ Vul | Vul/ Vul | ||

| 3.2 | Tyre dimensions, drive side | ø250 | ø250 | ø250 | ø250 | ø250 | ø250 | ø250 | ø250 | ||

| 3.3 | Tyre dimensions, load side | ø85 | ø85 | ø85 | ø85 | ø85 | ø85 | ø85 | ø85 | ||

| 3.4 | Castor wheel dimensions (diameter x width) | ø180 × 65 | ø180 × 65 | ø180 × 65 | ø180 × 65 | ø180 × 65 | ø180 × 65 | ø180 × 65 | ø180 × 65 | ||

| 3.5 | Number of wheels, drive/load side (x=driven) | 4 / 1x1 | 4 / 1 x 1 | 4 / 1x1 | 4 / 1 x 1 | 4 / 1 x 1 | 4 / 1 x 1 | 4 / 1 x 1 | 4 / 1 x 1 | ||

| 3.6 | Track width (centre of tyres), drive side | b10 | mm | 494 | 494 | 494 | 494 | 494 | 494 | 494 | 494 |

| 3.7 | Track width (centre of tyres), load side | b11 | mm | 355 | 355 | 365 | 365 | 326 / 356 | 326 / 356 | 365 | 365 |

| Dimensions | |||||||||||

| 4.2 | Height | h1 | mm | 1173 | 1394/ 2244 | 1173 | 1394/ 2244 | 1173 | 1394/ 2244 | 1173 | 1394/ 2244 |

| 4.4 | Lift height (see tables) | h3 | mm | 765 / 1115 | 765 / 1115 | 135 | 135 | 765 | 765 | 135 | 135 |

| 4.5 | Height with mast extended | h4 | mm | 1275 / 1625 | 1275 / 1625 | - | - | 1305 | 1305 | - | - |

| 4.8 | Seat height | h7 | mm | 123 | 150 | 123 | 150 | 123 | 150 | 123 | 150 |

| 4.14 | Height of the drivers's platform | h12 | mm | - | 1000 | - | 1000 | - | 1000 | - | 1000 |

| 4.15 | Fork height, fully lowered | h13 | mm | 85 | 85 | 85 | 85 | 90 | 90 | 85 | 85 |

| 4.19 | Overall length | l1 | mm | 2471 5) | 2471 5)

| 2421 5)

| 2421 5)

| 3728 4) 5)

| 3728 4) 5)

| 2421 4) 5)

| 2421 4) 5)

| |

| 4.20 | Length to fork face (includes fork thickness) | l2 | mm | 1321 5)

| 1321 5)

| 1271 5)

| 1271 5)

| 1353 4) 5)

| 1353 4) 5)

| 1271 5)

| 1271 5)

| |

| 4.21 | Overall width | b1/b2 | mm | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 |

| 4.22 | Fork dimensions (thickness, width, length) | s,e,l | mm | 56 / 186 / 950 - 1450 | 56 / 186 / 950 - 1450 | 6 / 175 / 900 - 3600 | 60 / 175 / 900 - 3600 | 70 / 194 / 2375, 2850 | 70 / 194 / 2375, 2850 | 60 / 175 / 900 - 3600 | 60 / 175 / 900 - 3600 |

| 4.25 | Outside width over forks (minimum/maximum) | b5 | mm | 540 / 570 | 540 / 570 | 480/ 660 | 480/ 660 | 520/ 550 | 520/ 550 | 480/ 660 | 480/ 660 |

| 4.32 | Ground clearance at centre of wheelbase, (forks lowered) | m2 | mm | 25 | 25 | 25 | 25 | 20 | 20 | 25 | 25 |

| 4.34 | Working aisle width with 800 × 1200 mm pallets, crosswise | Ast | mm | 2881 5)

| 2881 5)

| 2898 5)

| 2898 5)

| 4074 4) 5)

| 4074 4) 5)

| 2898 5)

| 2898 5)

| |

| 4.35 | Turning circle radius | Wa | mm | 2106 5)

| 2106 5)

| 2231 5)

| 2231 5)

| 2833 5)

| 2833 5)

| 2231 5)

| 2231 5)

| |

| Performance | |||||||||||

| 5.1 | Travel speed, with/without load | km/h | 9.0 / 9.0 (opt 9 / 13) 7) | 9.0 / 9.0 (opt 9 / 13) 7) | 9.0 / 9.0 (opt 9 / 13) | 9.0 / 9.0 (opt 9 / 13) 7) | 9.0 / 13.0 | 9.0 / 13.0 6) | 9.0 / 13.0 | 9.0 / 13.0 6) | |

| 5.2 | Lifting speed, with/without load | m/s | 0.20 / 0.41 | 0.20 / 0.41 | 0.04 / 0.05 | 0.04 / 0.05 | 0.10 / 0.23 | 0.10 / 0.23 | 0.03 / 0.05 | 0.03 / 0.05 | |

| 5.3 | Lowering speed, with/without load | m/s | 0.30 / 0.36 | 0.30 / 0.36 | 0.05 / 0.03 | 0.05 / 0.03 | 0.17 / 0.23 | 0.17 / 0.23 | 0.05 / 0.03 | 0.05 / 0.03 | |

| 5.7 | Gradeability, with/without load | % | 7 / 15 | 7 / 15 | 7 / 15 | 7 / 15 | 7 / 15 | 7 / 15 | 7 / 15 | 7 / 15 | |

| 5.10 | Service brakes (mechanical /hydraulic /electric /pneumatic) | Electric | Electric | Electric | Electric | Electric | Electric | Electric | Electric | ||

| Electric Motors | |||||||||||

| 6.1 | Drive motor capacity (60 min. short duty) | kW | 2.6 | 2.6 | 2.6 | 2.6 | 2.6 | 2.6 | 2.6 | 2.6 | |

| 6.2 | Lift motor output at 15% duty factor | kW | 2.2 | 2.2 | 1.2 | 1.2 | 2.2 | 2.2 | 1.2 | 1.2 | |

| 6.4 | Battery voltage/capacity at 5-hour discharge | V/Ah | 24 / 465 - 620 | 24 / 465 - 620 | 24 / 465 - 620 | 24 / 465 - 620 | 24 / 465 - 620 | 24 / 465 - 620 | 24 / 465 - 620 | 24 / 465 - 620 | |

| 6.5 | Battery weight | kg | 355 - 493 | 355 - 493 | 355 - 493 | 355 - 493 | 355 - 493 | 355 - 493 | 355 - 493 | 355 - 493 | |

| 6.6 | Energy consumption according to VDI 60 cycle | kWh/h | 0.37 | 0.37 | 0.37 | 0.37 | 0.44 | 0.44 | 0.4 | 0.4 | |

| Miscellaneous | |||||||||||

| 8.1 | Type of drive control | Stepless | Stepless | Stepless | Stepless | Stepless | Stepless | Stepless | Stepless | ||

| 8.4a | Level of noise at the ear level of the driver according to EN 12 053:2001 and EN ISO 4871 in work LpAZ | dB(A) | 62 3) | 62 3) | 62 3) | 62 3) | 62 3) | 62 3) | 62 3) | 62 3) | |

| 8.4b | Level of noise at the ear level of the driver according to EN 12 053:2001 and EN ISO 487, drive/lift/idle LpAZ | dB(A) | 73 / 62 / - 3) | 73 / 62 / - 3) | 73 / 62 / - 3) | 73 / 62 / - 3) | 73 / 62 / - 3) | 73 / 62 / - 3) | 73 / 62 / - 3) | 73 / 62 / - 3) | |

| 8.6a | Whole-body vibration (EN 13 059:2002) | m/s² | 0.6 | 0.6 | 0.6 | 0.6 | 0.7 | 0.7 | 0.6 | 0.6 | |

| 8.7a | Hand-arm vibration (EN 13 059:2002) | m/s² | < 2.5 | < 2.5 | < 2.5 | < 2.5 | < 2.5 | < 2.5 |