High performance

Intuitive operation

The compact and versatile AXiA EM 1.25 and 1.60 tonne platform stacker series is the perfect choice for high level stacking applications, order picking, and transport operations in narrow spaces.

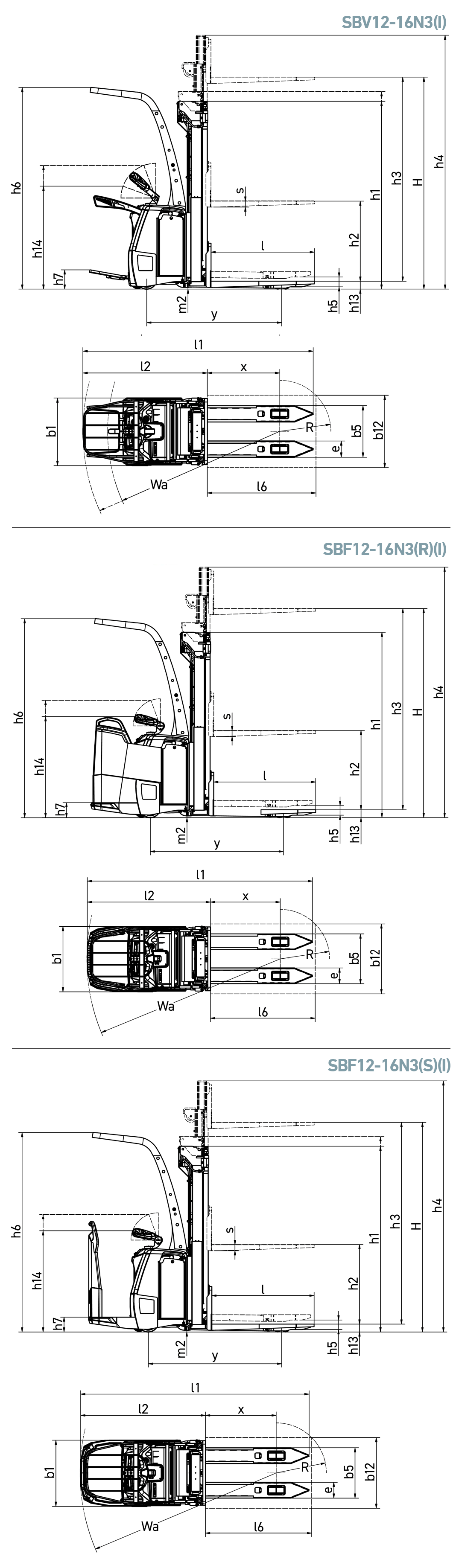

The series is available in foldable platform models with optional sidebars for use in narrow spaces, fixed platform rear entry models for fast operations where maximum operator protection is required, and fixed platform side entry models for easy on-off access on both sides for picking applications. AXiA EM has a sturdy 4-point chassis where the drive system is designed to increase traction and stabilisation proportional to the load. This keeps the truck consistently stable for safe, productive performance and confident operation.

Plus, a choice of modes (Easy, ECO & PRO) allows users of all skill levels to work to the best of their abilities. An extensive range of mast models are available with AXiA EM to ensure the truck is aptly suited to the application. Duplex masts offer lift heights from 2690 mm to 4200 mm, while Triplex masts deliver lift heights from 4350 mm to 5400 mm.

An optional Initial Lift allows AXiA EM to serve as a double pallet handler for greater efficiency, with exceptional ground clearance for ease of use on uneven floors. AXiA EM has a built-in Li-ion battery for fast opportunity charging, making it the ideal stacker to support intense 24/7 operations that demand maximum uptime.

| Model | Load Capacity |

|---|---|

| SBF12N3IR | 1250 kg |

| SBF12N3IS | 1250 kg |

| SBF12N3R | 1250 kg |

| SBF12N3S | 1250 kg |

| SBV12N3 | 1250 kg |

| SBV12N3I | 1250 kg |

| SBF16N3IR | 1600 kg |

| SBF16N3IS | 1600 kg |

| SBF16N3R | 1600 kg |

| SBF16N3S | 1600 kg |

| SBF16N3SR | 1600 kg |

| SBF16N3SS | 1600 kg |

| SBV16N3 | 1600 kg |

| SBV16N3I | 1600 kg |

| SBV16N3S | 1600 kg |

The very compact chassis design allows the machine to work in much tighter aisles - releasing valuable storage space and making it safer to operate.

Switchable modes set the truck's behaviours and performance to better match requirements for operator skill levels, performance and economy. Easy mode is aimed at less experienced drivers, ECO mode can extend the time between charges for maximum uptime, and PRO mode offers maximum available performance.

IP65-rated tiller head with large, easy-to-reach controls ergonomically placed for greater operating comfort and less fatigue through shifts.

Automatically adjusts truck speed according to steer angle for increased operator and site safety, improved productivity and reduced tyre wear.

This option allows for quick charging, while minimising maintenance - avoiding the need for costly extra batteries and time-consuming changeovers. (Option)

Controlled Cornering System

The truck senses both the velocity of the steering and the angle of a turn and reduces speed early for maximum stability and accurate, positive cornering.

Ergonomic ErgoSteer tiller head

Best-in-class, impact-resistant tiller head with large, easy-to-reach buttons placed at a patented ergonomic distance for reduced fatigue and safer operation. IP65 rated.

Adjustable EasyRide electric dampening

Unique electric dampening capability allows operator to adjust the platform to their weight or preference - ideal for applications on ramps, uneven floors, and working over long distances. (Option on platform trucks)

Choice of three operating modes (PRO, ECO and Easy)

Different driver modes: PRO for advanced drivers, ECO for low energy consumption, Easy for sensitive goods or beginners.

Damped platform

Foldable platforms and side/rear entry platforms are damped to ensure minimum vibrations and bumps for greater operator comfort. (All models)

Tried, tested and proven in the field, lead-acid batteries have been the long-standing choice for companies employing electric lift trucks. However, with long charging times, demanding maintenance requirements, the need for extra batteries, and high risk of operator misuse, it can be a challenge. Fortunately, there's a new battery system on the block: Li-ion from Mitsubishi Forklift Trucks.

Designed to meet your business' demands - including multi-shift (24/7) operations - without the need for spare batteries, our high-performance Li-ion battery system is up to 40 per cent more efficient than lead-acid counterparts. Plus, it's virtually error-proof, thanks to its ultra-low-maintenance design which prevent cell damage.

Exceptional, zero-emissions efficiency

40% more efficient than lead-acid batteries and free from gases.

Ultra-low maintenance design

Just a full charge each week to activate cell balancing, as well as an annual CSV export/update.

No space required

With no need for charging areas, there's no cost for set up and you can keep your profitable space just that: profitable.

Quick charge capabilities

Just 15 minutes is all your battery needs to keep your truck going a few more hours. (It only takes 1 to 2 hours to fully charge a completely discharged battery.)

Higher sustained voltage

This ensures more consistent lifting and driving performance, which is particularly noticeable towards the end of a shift.

TriCOM Technology

Helps to deliver exceptionally high system efficiency (up to 97%)

| Characteristics | ||||||||||||||||||

| 1.2 | Manufacturer's model designation | SBF12N3IR | SBF12N3IS | SBF12N3R | SBF12N3S | SBV12N3 | SBV12N3I | SBF16N3IR | SBF16N3IS | SBF16N3R | SBF16N3S | SBF16N3SR | SBF16N3SS | SBV16N3 | SBV16N3I | SBV16N3S | ||

| 1.3 | Power source: (battery, diesel, LP gas, petrol) | Battery | Battery | Battery | Battery | Battery | Battery | Battery | Battery | Battery | Battery | Battery | Battery | Battery | Battery | Battery | ||

| 1.4 | Operator type: pedestrian, (operator)-standing, -seated | Stand-on | Stand-on | Stand-on | Stand-on | Pedestrian / Stand-on | Pedestrian / Stand-on | Stand-on | Stand-on | Stand-on | Stand-on | Stand-on | Stand-on | Pedestrian / Stand-on | Pedestrian / Stand-on | Pedestrian / Stand-on | ||

| 1.5 | Load capacity | Q | kg | 1250 | 1250 | 1250 | 1250 | 1250 | 1250 | 1600 | 1600 | 1600 | 1600 | 1600 | 1600 | 1600 | 1600 | 1600 |

| 1.6 | Load centre distance | c | mm | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 | 600 |

| 1.8 | Load wheel axle to fork face (forks lowered) | x | mm | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 8001) | 8001) | 8001) | 8001) | 8001) | 800 | 8001) |

| 1.9 | Wheelbase | y | mm | 1503 | 1503 | 1429 | 1429 | 1429 | 1503 | 1533 | 1533 | 15032) | 15032) | 15432) | 15432) | 15032) | 1533 | 15432) |

| Weight | ||||||||||||||||||

| 2.1b | Truck weight without load, with maximum battery weight | kg | 1470 | 1470 | 1370 | 1370 | 1300 | 1400 | 1680 | 1680 | 1580 | 1580 | 1650 | 1650 | 1430 | 1530 | 1580 | |

| 2.2 | Axle loadings with nominal load & maximum battery weight, drive/load side | kg | 1005 / 141013) | 1020 / 149513) | 1355 / 189513) | 1355 / 189513) | 1320 / 183513) | 1235 / 197513) | 1320 / 184513) | |||||||||

| 2.3 | Axle loadings without load & with maximum battery weight, drive/load side | kg | 825 / 31013) | 855 / 37513)) | 1175 / 44513) | 1175 / 44513) | 1130 / 39013)) | 1095 / 48513) | 1025 / 425113) | |||||||||

| Wheels, Drive Train | ||||||||||||||||||

| 3.1 | Tyres: PT=Power Thane, Vul=Vulkollan, drive/load side | Vul / Vul | Vul / Vul | Vul / Vul | Vul / Vul | Vul / Vul | Vul / Vul | Vul / Vul | Vul / Vul | Vul / Vul | Vul / Vul | Vul / Vul | Vul / Vul | Vul / Vul | Vul / Vul | Vul / Vul | ||

| 3.2 | Tyre dimensions, drive side | 235 x 75 | 235 x 75 | 235 x 75 | 235 x 75 | 235 x 75 | 235 x 75 | 235 x 75 | 235 x 75 | 235 x 75 | 235 x 75 | 235 x 75 | 235 x 75 | 235 x 75 | 235 x 75 | 235 x 75 | ||

| 3.3 | Tyre dimensions, load side | 85 x 763) | 85 x 763) | 85 x 763) | 85 x 763) | 85 x 763) | 85 x 763) | 85 x 763) | 85 x 763) | 85 x 763) | 85 x 763) | 85 x 763) | 85 x 763) | 85 x 763) | 85 x 763) | 85 x 763) | ||

| 3.4 | Castor wheel dimensions (diameter x width) | 150 x 55 | 150 x 55 | 150 x 55 | 150 x 55 | 150 x 55 | 150 x 55 | 150 x 55 | 150 x 55 | 150 x 55 | 150 x 55 | 150 x 55 | 150 x 55 | 150 x 55 | 150 x 55 | 150 x 55 | ||

| 3.5 | Number of wheels, drive/load side (x=driven) | 43) / 1x + 1 | 43) / 1x + 1 | 43) / 1x + 1 | 43) / 1x + 1 | 43) / 1x + 1 | 43) / 1x + 1 | 43) / 1x + 1 | 43) / 1x + 1 | 43) / 1x + 1 | 43) / 1x + 1 | 43) / 1x + 1 | 43) / 1x + 1 | 43) / 1x + 1 | 43) / 1x + 1 | 43) / 1x + 1 | ||

| 3.6 | Track width (centre of tyres), drive side | b10 | mm | 497 | 497 | 497 | 497 | 497 | 497 | 497 | 497 | 497 | 497 | 497 | 497 | 497 | 497 | 497 |

| 3.7 | Track width (centre of tyres), load side | b11 | mm | 390 | 390 | 402 | 402 | 402 | 390 | 390 | 390 | 402 | 402 | 985 / 11853) | 985 / 11853) | 402 | 390 | 985 / 11853) |

| Dimensions | ||||||||||||||||||

| 4.2a | Height with mast lowered | h1 | mm | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ |

| 4.2b | Height | h1 | mm | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ |

| 4.3 | Free lift (see tables) | h2 | mm | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ |

| 4.4 | Lift height (see tables) | h3 | mm | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ |

| 4.5 | Height with mast extended | h4 | mm | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ | ‡ |

| 4.6 | Initial Lift | h5 | mm | 110 | 110 | 110 | 110 | 110 | 110 | |||||||||

| 4.7 | Height to top of overhead guard | h6 | mm | 2283 | 2283 | 2283 | 2283 | 2283 | 2283 | 2283 | 2283 | 2283 | 2283 | 2283 | 2283 | 2283 | 2283 | 2283 |

| 4.8 | Seat height | h7 | mm | 170 | 170 | 170 | 170 | 171 | 171 | 170 | 170 | 170 | 170 | 170 | 170 | 171 | 171 | 171 |

| 4.9 | Height of tiller arm/steering console (min./max.) | h14 | mm | 1119 / 1428 | 1130 / 12978) | 1119 / 1428 | 1130 / 12978) | 1099 / 1512 | 1099 / 1512 | 1119 / 1428 | 1130 / 12978) | 1119 / 1428 | 1130 / 12978) | 1119 / 1428 | 1130 / 12978) | 1099 / 1512 | 1099 / 1512 | 1099 / 1512 |

| 4.10 | Height of support legs | 87 | 87 | 82 | 82 | 82 | 87 | 87 | 87 | 80 | 80 | 923) | 923) | 80 | 87 | 923) | ||

| 4.15 | Fork height, fully lowered | h13 | mm | 93 | 93 | 85 | 89 | 85 | 90 | 93 | 93 | 83 | 89 | 55 | 55 | 83 | 90 | 55 |

| 4.19 | Overall length | l1 | mm | 2556 | 2556 | 2482 | 2482 | 2090 / 24504) 14) | 2163 / 25234) 14) | 2585 | 2585 | 2556 | 2556 | 2576 | 2576 | 2164 / 25254) 14) | 2193 / 25544) 14) | 2184 / 25454) 14) |

| 4.20 | Length to fork face (includes fork thickness) | l2 | mm | 1386 | 1386 | 1312 | 1312 | 920 / 12804) | 993 / 13534) 14 | 1415 | 1415 | 1386 | 1386 | 1426 | 1426 | 994 / 13554) 14) | 1023 / 13843) 14) | 1034 / 13954) 14) |

| 4.21 | Overall width | b1/b2 | mm | 748 | 748 | 748 | 748 | 748 | 748 | 748 | 748 | 748 | 748 | 1115 / 1315 3) 17) | 1115 / 13153) 17) | 748 | 748 | 1115 / 13153) 17) |

| 4.22 | Fork dimensions (thickness, width, length) | s,e,l | mm | 70 / 180 / 1170 | 70 / 180 / 1170 | 70 / 180 / 1170 | 70 / 180 / 1170 | 70 / 180 / 1170 | 70 / 180 / 1170 | 70 / 180 / 1170 | 70 / 180 / 1170 | 70 / 180 / 11705) | 70 / 180 / 11705) | 40 / 100 / 1150 5) | 40 / 100 / 11505) | 70 / 180 / 11705) | 70 / 180 / 1170 | 40 / 100 / 11505) |

| 4.23 | Fork carriage to DIN 15 173 A/B/no | FEM 2/A | FEM 2/A | FEM 2/A | ||||||||||||||

| 4.24 | Fork carriage width | b3 | mm | 670 | 670 | 670 | 670 | 670 | 670 | 730 | 730 | 730 | 730 | 840 | 840 | 730 | 730 | 840 |

| 4.25 | Outside width over forks (minimum/maximum) | b5 | mm | 570 | 570 | 570 | 570 | 570 | 570 | 570 | 570 | 5706) | 5706) | 316 / 773 | 316 / 773 | 5706) | 570 | 316 / 773 |

| 4.26 | Inner width of support legs | b4 | mm | N/A7) | N/A7) | N/A7) | N/A7) | N/A7) | N/A7) | N/A7) | N/A7) | N/A7) | N/A7) | 855 / 10557) | 855 / 105517) | N/A17) | N/A17) | 855 / 105517) |

| 4.32 | Ground clearance at centre of wheelbase, (forks lowered) | m2 | mm | 20-130 | 20-130 | 32 | 32 | 32 | 20-130 | 20-130 | 20-130 | 25 | 25 | 303) | 303) | 25 | 20-130 | 303) |

| 4.33a | Working aisle width (Ast) with 1000 × 1200 mm pallets, load crosswise, platform up/down | Ast | mm | 30632) | 30632) | |||||||||||||

| 4.33c | Working aisle width (Ast) with 800 × 1200 mm pallets, load lengthwise, platform up/down | Ast | mm | 2688 / 30274) | ||||||||||||||

| 4.34a | Working aisle width (Ast) with 800 × 1200 mm pallets, load lengthwise, platform up/down | Ast | mm | 2956 | 2956 | 2878 | 2878 | 2986 | 2986 | 2957 | 2957 | 29972) | 29972) | |||||

| 4.34c | Working aisle width (Ast) with 800 × 1200 mm pallets, load lengthwise, platform up/down | Ast | mm | 2509 / 28464)) [28419)] | 2581 / 29194) [29149)] | 2582 / 29214) [29159)] | 2611 / 29504) [29449)] | 2622 / 29612) 4) [29559)] | ||||||||||

| 4.35 | Turning circle radius | Wa | mm | 2190 | 2190 | 2112 | 2112 | 1743 / 20804) [20759)] | 1815 / 21534) [21489)] | 2220 | 2220 | 2191 | 2191 | 22312) | 22312) | 1816 / 21554) [21499)] | 1845 / 21844) [21789)] | 1856 / 21952) 4) [21899)] |

| Performance | ||||||||||||||||||

| 5.1 | Travel speed, with/without load | km/h | 8.5 / 8.5 | 8.5 / 8.5 | 8.5 / 8.5 | 8.5 / 8.5 | 6.0 / 6.010) 8.5 / 8.511) | 6.0 / 6.010) 8.5 / 8.511) | 8.5 / 8.5 | 8.5 / 8.5 | 8.5 / 8.5 | 8.5 / 8.5 | 8.5 / 8.5 | 8.5 / 8.5 | 6.0 / 6.010) 8.5 / 8.5111) | 6.0 / 6.010) 8.5 / 8.511) | 6.0 / 6.010) 8.5 / 8.511) | |

| 5.2 | Lifting speed, with/without load | m/s | 0.20 / 0.34 | 0.20 / 0.34 | 0.20 / 0.34 | 0.20 / 0.34 | 0.20 / 0.34 | 0.20 / 0.34 | 0.16 / 0.28 | 0.16 / 0.28 | 0.16 / 0.28 | 0.16 / 0.28 | 0.15 / 0.24 | 0.15 / 0.24 | 0.16 / 0.28 | 0.16 / 0.28 | 0.15 / 0.24 | |

| 5.3 | Lowering speed, with/without load | m/s | 0.47 / 0.33 | 0.47 / 0.33 | 0.47 / 0.40 | 0.47 / 0.40 | 0.47 / 0.40 | 0.47 / 0.33 | 0.42 / 0.36 | 0.42 / 0.36 | 0.42 / 0.41 | 0.42 / 0.41 | 0.33 / 0.30 | 0.33 / 0.30 | 0.42 / 0.41 | 0.42 / 0.36 | 0.33 / 0.30 | |

| 5.7 | Gradeability, with/without load | % | 11.4 / 15.0 | 11.4 / 15.0 | 8.7 / 8.7 | 8.7 / 8.7 | 8.7 / 8.7 | 11.9 / 17.2 | 10.9 / 15.0 | 10.9 / 15.0 | 6.1 / 6.1 | 6.1 / 6.1 | 6.1 / 6.1 | 6.1 / 6.1 | 6.1 / 6.1 | 11.3 / 17.2 | 6.1 / 6.1 | |

| 5.8 | Maximum gradeability, with/without load | s | 21.8 / 10.4 | 21.8 / 10.4 | 19.7 / 9.9 | |||||||||||||

| 5.9 | Acceleration time (10 metres) with/without load | s | 5.7 / 5.313) | 5.7 / 5.313) | 5.7 / 5.313) | 5.7 / 5.313) | 5.7 / 5.313) | 5.7 / 5.313) | 6.3 / 5.313) | 6.3 / 5.313) | 6.3 / 5.313) | 6.3 / 5.313) | 6.3 / 5.313) | 6.3 / 5.313) | 6.3 / 5.313) | 6.3 / 5.313) | 6.3 / 5.313) | |

| 5.10 | Service brakes (mechanical /hydraulic /electric /pneumatic) | Electric12) | Electric12) | Electric12) | Electric12) | Electric12) | Electric12) | Electric12)) | Electric12) | Electric12) | Electric12) | Electric12) | Electric12) | Electric12) | Electric12) | Electric12) | ||

| Electric Motors | ||||||||||||||||||

| 6.1 | Drive motor capacity (60 min. short duty) | kW | 2.4 | 2.4 | 2.4 | 2.4 | 2.4 | 2.4 | 2.4 | 2.4 | 2.4 | 2.4 | 2.4 | 2.4 | 2.4 | 2.4 | 2.4 | |

| 6.2 | Lift motor output at 15% duty factor | kW | 3.015) | 3.015) | 3.015) | 3.015) | 3.015) | 3.015) | 3.015) | 3.015) | 3.015) | 3.015) | 3.015) | 3.015) | 3.015) | 3.015) | 3.015) | |

| 6.4 | Battery voltage/capacity at 5-hour discharge | V/Ah | 24 / 270-400 | 24 / 270-400 | 24 / 270-400 | 24 / 270-400 | 24 / 270-400 | 24 / 270-400 | 24 / 270-400 | 24 / 270-400 | 24 / 270-400 | 24 / 270-400 | 24 / 270-400 | 24 / 270-400 | 24 / 270-400 | 24 / 270-400 | 24 / 270-400 | |

| 6.5 | Battery weight | kg | 285-350 | 285-350 | 285-350 | 285-350 | 285-350 | 285-350 | 285-350 | 285-350 | 285-350 | 285-350 | 285-350 | 285-350 | 285-350 | 285-350 | 285-350 | |

| 6.6a | Energy consumption according to DIN EN 16796 | kWh/h | 0.6816) | 0.6816) | 0.6816) | 0.6816) | 0.6816) | 0.6816) | 0.7216) | 0.7216) | 0.7216) | 0.7216) | 0.7216) | 0.7216) | 0.7216) | 0.7216) | 0.7216) | |

| Miscellaneous | ||||||||||||||||||

| 8.1 | Type of drive control | AC | AC | AC | AC | AC | AC | AC | AC | AC | AC | AC | AC | AC | AC | AC | ||

| 10.7 | Sound pressure level at the driver's seat | dB (A) | <70 dB(A) | <70 dB(A) | <70 dB(A) | <70 dB(A) | <70 dB(A) | <70 dB(A) | <70 dB(A) | <70 dB(A) | <70 dB(A) | <70 dB(A) | <70 | <70 | <70 dB(A) | <70 dB(A) | <70 |