POWER UP PERFORMANCE...

DRIVE DOWN RUNNING COSTS

Developed to help your operator achieve maximum productivity, while minimising running costs, GRENDiA ES sets the highest standards for IC engine counterbalance forklift trucks.

With its exceptional fuel economy, durable components and low-maintenance design, GRENDiA makes perfect business sense. What's more, it comes with a package of advanced features, fitted as standard, that offers true value for money.

Fast, stable and exceptionally powerful, GRENDiA forklift trucks offer a potent combination of high efficiency and low emissions in line with Euro Stage V regulations.

To that, Mitsubishi Forklift Trucks has added a host of ergonomic features to maximise comfort, control and precision. The result is a forklift that can be relied upon to deliver top performance, whatever the application, whatever the conditions.

| Model | Load Capacity |

|---|---|

| FG15N | 1500 kg |

| FG18N | 1750 kg |

| FG20CN | 2000 kg |

| FG20N | 2000 kg |

| FG25N | 2500 kg |

| FG30N | 3000 kg |

| FG35N | 3500 kg |

Increases safety by isolating hydraulic and drive functions when operator not present for 2 seconds or longer. PIN-access as standard prevents misuse by unauthorised operators.

This high-power 'brain' allows multiple engine and electronic functions to occur simultaneously, constantly adjusting and optimising performance: ensuring power and fuel consumption.

Complete sealing of underside reduces risk of damage from foreign objects, such as shrinkwrap, entering engine compartment. It also reduces noise and eliminates safety issues caused by airborne dust particles.

Industrial-designed engine delivers industry-leading, high torque and power at low revolutions for a long, trouble-free life. Provides legendary reliability and longevity whilst delivering performance - combined with the lowest fuel consumption.

To protect the heart of the machine, in an overheat situation, the engine protection system offers two stages of protection. First it slows the machine down, then it shuts it down to protect it.

Vision is fundamental to any safe fork truck operation. GRENDiA ES offers through mast vision for increased safety and reduced damage costs.

For optimum safety, Mitsubishi Forklift Trucks fits LED lights as standard. No need to replace working light bulbs. Fully automatic for safety, they provide greater brightness than halogen with no power consumption.

Improves safety of work area as use of the machine is restricted to authorised operators only.

Isolating the chassis from road impact ensure smoother operating conditions, while isolating the drivetrain protects the transmission and chassis from continued use in difficult applications.

Uniquely fitted to all LPG models in line with the Mitsubishi Forklift Trucks uncompromising commitment to safety. Ensures industry-leading low fuel consumption, low harmful emissions and high-power performance.

Three-way catalytic converter

- fitted as standard - significantly reduces exhaust emissions to one of the industry's lowest levels. (LPG models only.)

Integrated Presence System (IPS)

prevents all movement of the truck and its mast if the operator is not seated, as well as providing a seatbelt warning light and parking brake alarm.

Touch-sensitive fingertip controls (optional)

are spring-loaded for a natural feeling; the gentler the touch, the finer the control.

F2 thumb-control button (optional)

allows you to double the number of controls - without taking your eyes off the load.

Heavy-duty clear-view mast

offers vision of fork tip and load, for faster cycle times and reduced damage.

Robust construction

has been designed and rigorously tested to ensure high stability, rigidity and protection.

Unparalleled 360° visibility

An optimised mast, wheel, dashboard and counterweight design maximises visibility to load, forks, front and rear wheels - giving safe, confident operation in tight spaces.

ErgoCentric describes our approach to meeting your operator's ergonomic needs.

You'll see this approach throughout the truck, but particularly in the operator's compartment where providing spacious, uncluttered access and maximum visibility are top priorities.

IPS prevents all truck and mast movement if the operator is not seated to prevent accidental lifting, lowering, tilting and travel.

In addition, the system automatically gives operators essential warnings and reminders to encourage safety.

Even the best trucks in the world need maintenance and repair, and Mitsubishi Forklift Trucks have built our reputation on low maintenance and little downtime.

RapidAccess features give operators and engineers quick and easy entry to all areas for checks and maintenance - saving time and money.

Our Belly Seal system protects your truck and your workforce from damage caused by dust.

Comprising a belly plate and other unique sealing components, it defends the truck's workings from debris on the floor, while also preventing the engine from spreading dust and dirt into the air.

The unique fully adjustable, full-length armrest supports the arm and palm to keep operators safe and comfortable, reducing the risk of RSIs associated with intensive operations.

With more than two decades of producing fingertip controls, our designers have consistently built units considered by many to be the best in the industry. Ideal for applications where precise control is needed, they can even be operated using heavy protective gloves.

Programmable sensitivity

Meets the needs of different applications and operators.

Touch-sensitive fingertip controls

Spring-loaded for a natural feel. The lighter the touch, the finer the control.

Modulated response curves

Optimised for natural movement - for precise, effortless control.

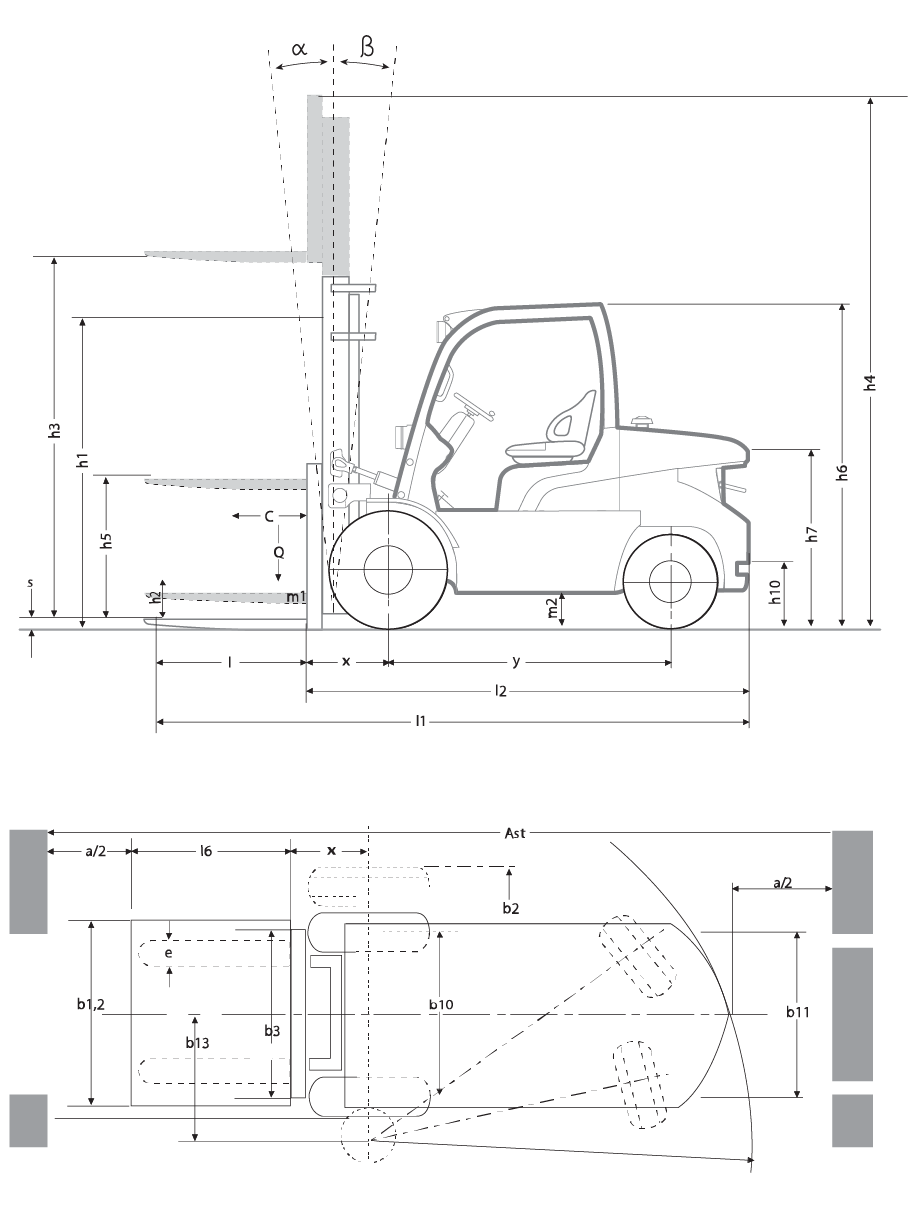

| Characteristics | ||||||||||

| 1.2 | Manufacturer's model designation | FG15N | FG18N | FG20CN | FG20N | FG25N | FG30N | FG35N | ||

| 1.3 | Power source: (battery, diesel, LP gas, petrol) | LPG | LPG | LPG | LPG | LPG | LPG | LPG | ||

| 1.4 | Operator type: pedestrian, (operator)-standing, -seated | Seated | Seated | Seated | Seated | Seated | Seated | Seated | ||

| 1.5 | Load capacity | Q | kg | 1500 | 1750 | 2000 | 2000 | 2500 | 3000 | 3500 |

| 1.6 | Load centre distance | c | mm | 500 | 500 | 500 | 500 | 500 | 500 | 500 |

| 1.8 | Load distance, axle to fork face (forks lowered) | x | mm | 400 | 400 | 415 | 455 | 460 | 495 | 495 |

| 1.9 | Wheelbase | y | mm | 1400 | 1400 | 1400 | 1600 | 1600 | 1700 | 1700 |

| Weight | ||||||||||

| 2.1 | Truck weight without load, with maximum battery weight | kg | 2490 | 2690 | 3010 | 3300 | 3600 | 4240 | 4630 | |

| 2.2 | Axle loading with maximum load, front/rear (simplex mast, lowest lift height) | kg | 3510 / 460 | 3870 / 540 | 4320 / 660 | 4600 / 670 | 5390 / 680 | 6470 / 770 | 7180 / 950 | |

| 2.3 | Axle loading without load, front/rear (simplex mast, lowest lift height) | kg | 1040 / 1430 | 990 / 1670 | 1010 / 1970 | 1410 / 1860 | 1390 / 2180 | 1710 / 2530 | 1630 / 3000 | |

| Wheels, Drive Train | ||||||||||

| 3.1 | Tyres: V=solid, L=pneumatic, SE=solid pneumatic - front/rear | SE / SE | SE / SE | SE / SE | SE / SE | SE / SE | SE / SE | SE / SE | ||

| 3.2 | Tyre dimensions, front | 6.50 - 10 - 10PR | 6.50 - 10 - 10PR | 6.50 - 10 / 5.00 | 7.00 - 12 - 12PR | 7.00 - 12 - 12PR | 28 × 9 - 15 - 12PR | 250 - 15 - 12PR | ||

| 3.3 | Tyre dimensions, rear | 5.00 - 8 - 8PR | 5.00 - 8 - 8PR | 5.00 - 8 / 3.00 | 6.00 - 9 - 10PR | 6.00 - 9 - 10PR | 6.50 - 10 - 10PR | 6.50 - 10 - 10PR | ||

| 3.5 | Number of wheels, front/rear (x=driven) | 2 x / 2 | 2 x / 2 | 2 x / 2 | 2 x / 2 | 2 x / 2 | 2 x / 2 | 2 x / 2 | ||

| 3.6 | Track width (center of tyres), drive side | b10 | mm | 890 | 890 | 890 | 960 | 960 | 1060 | 1060 |

| 3.7 | Track width (center of tyres), load side | b11 | mm | 900 | 900 | 900 | 980 | 980 | 980 | 980 |

| Dimensions | ||||||||||

| 4.1 | Mast tilt, forwards/backwards | a / b | ° | 6 / 10 | 6 / 10 | 6 / 10 | 6 / 10 | 6 / 10 | 6 / 10 | 6 / 10 |

| 4.2 | Height with mast lowered (see tables) | h1 | mm | 2140 | 2140 | 2140 | 2150 | 2150 | 2170 | 2300 |

| 4.3 | Free lift (see tables) | h2 | mm | 115 | 115 | 115 | 140 | 140 | 145 | 145 |

| 4.4 | Lift height (see tables) | h3 | mm | 3290 | 3290 | 3290 | 3300 | 3300 | 3270 | 3300 |

| 4.5 | Height with mast extended | h4 | mm | 4340 | 4340 | 4340 | 4360 | 4360 | 4330 | 4360 |

| 4.7 | Height to top of overhead guard | h6 | mm | 2140 | 2140 | 2140 | 2145 | 2145 | 2165 | 2175 |

| 4.8 | Seat height | h7 | mm | 930 | 930 | 930 | 940 | 940 | 990 | 990 |

| 4.12 | Tow coupling height | h10 | mm | 290 | 290 | 290 | 310 | 310 | 330 | 340 |

| 4.19 | Overall length | l1 | mm | 3330 | 3370 | 3425 | 3560 | 3630 | 3805 | 3865 |

| 4.20 | Length to fork face (includes fork thickness) | l2 | mm | 2260 | 2300 | 2355 | 2485 | 2560 | 2735 | 2795 |

| 4.21 | Overall width | b1/b2 | mm | 1065 / - | 1065 / - | 1065 / - | 1150 / 1640 | 1150 / 1640 | 1275 / 1690 | 1290 / 1690 |

| 4.22 | Fork dimensions (thickness, width, length) | s,e,l | mm | 35 x 100 x 1070 | 35 x 100 x 1070 | 35 x 100 x 1070 | 40 x 100 x 1070 | 40 x 100 x 1070 | 45 x 125 x 1070 | 45 x 125 x 1070 |

| 4.23 | Fork carriage to DIN 15 173 A/B/no | 2A | 2A | 2A | 2A | 2A | 3A | 3A | ||

| 4.24 | Fork carriage width | b3 | mm | 920 | 920 | 920 | 1000 | 1000 | 1000 | 1000 |

| 4.31 | Ground clearance under mast, with load | m1 | mm | 110 | 110 | 110 | 115 | 115 | 135 | 150 |

| 4.32 | Ground clearance at centre of wheelbase, with load (forks lowered) | m2 | mm | 135 | 135 | 135 | 135 | 135 | 165 | 170 |

| 4.33 | Working aisle width with 1000 × 1200 mm pallets, crosswise | Ast | mm | 3550 | 3580 | 3635 | 3855 | 3890 | 4075 | 4135 |

| 4.34a | Working aisle width (Ast) with 800 × 1200 mm pallets, load lengthwise, platform up/down | Ast | mm | 3350 | 3380 | 3435 | 3655 | 3690 | 3875 | 3935 |

| 4.34b | Working aisle width (Ast3) with 800 × 1200 mm pallets, load lengthwise, platform up/down | Ast3 | mm | 3750 | 3780 | 3825 | 4055 | 4090 | 4275 | 4335 |

| 4.35 | Turning circle radius | Wa | mm | 1950 | 1980 | 2020 | 2200 | 2230 | 2380 | 2440 |

| 4.36 | Minimum distance between centres of rotation | b13 | mm | 555 | 555 | 555 | 715 | 715 | 780 | 780 |

| Performance | ||||||||||

| 5.1 | Travel speed, with/without load | km/h | 19.0 / 19.5 | 19.0 / 19.5 | 19.0 / 19.5 | 19.0 / 19.5 | 19.0 / 19.5 | 19.0 / 19.5 | 19.0 / 19.5 | |

| 5.2 | Lifting speed, with/without load | m/s | 0.64 / 0.65 | 0.64 / 0.65 | 0.64 / 0.65 | 0.59 / 0.61 | 0.59 / 0.61 | 0.52 / 0.53 | 0.43 / 0.44 | |

| 5.3 | Lowering speed, with/without load | m/s | 0.52 / 0.50 | 0.52 / 0.50 | 0.52 / 0.50 | 0.50 / 0.50 | 0.50 / 0.50 | 0.53 / 0.50 | 0.42 / 0.40 | |

| 5.5 | Rated drawbar pull, with/without load | N | 17400 / 16900 | 17400 / 16800 | 17300 / 17100 | 17100 / 16800 | 17100 / 16700 | 21800 / 21400 | 19900 / 19800 | |

| 5.6 | Maximum drawbar pull, with/without load (5 min short duty) | -/- | -/- | -/- | -/- | -/- | -/- | -/- | ||

| 5.7 | Gradeability, with/without load | % | 49 / 93 | 43 / 81 | 37 / 70 | 35 / 60 | 30 / 53 | 32 / 60 | 26 / 48 | |

| 5.8 | Maximum gradeability, with/without load | s | -/- | -/- | -/- | -/- | -/- | -/- | -/- | |

| 5.9 | Acceleration time (10 metres) with/without load | s | -/- | -/- | -/- | -/- | -/- | -/- | -/- | |

| 5.10 | Service brakes (mechanical /hydraulic /electric /pneumatic) | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic | ||

| IC Engine | ||||||||||

| 7.1 | Manufacturer / Type | GCT GK21E | GCT GK21E | GCT GK21E | GCT GK21E | GCT GK21E | GCT GK25E | GCT GK25E | ||

| 7.2 | Rated output to ISO 1585 | kW | 41 | 41 | 41 | 41 | 41 | 46.9 | 46.9 | |

| 7.3 | Rated speed to DIN 70 020 | rpm | 2700 | 2700 | 2700 | 2700 | 2700 | 2700 | 2700 | |

| 7.4 | Number of cylinders / cubic capacity | / cm³ | 4 / 2065 | 4 / 2065 | 4 / 2065 | 4 / 2065 | 4 / 2065 | 4 / 2488 | 4 / 2488 | |

| 7.5 | Fuel consumption according to VDI 60 cycle | L/h / kg/h | - / 2.10 | - / 2.40 | - / 2.40 | - / 2.55 | - / 3.20 | - / 3.10 | - / 3.50 | |

| 7.7a | Maximum torque at engine speed | rpm | 1800 | 1800 | 1800 | 1800 | 1800 | 1600 | 1600 | |

| Miscellaneous | ||||||||||

| 8.1 | Type of drive control | Powershift 1 / 1 | Powershift 1 / 1 | Powershift 1 / 1 | Powershift 1 / 1 | Powershift 1 / 1 | Powershift 1 / 1 | Powershift 1/1 | ||

| 8.2 | Maximum operating pressure for attachments | bar | 180 | 180 | 180 | 180 | 180 | 180 | 180 | |

| 8.3 | Oil flow for attachments | L/min | 60 | 60 | 60 | 73 | 73 | 73 | 73 | |

| 8.4 | Noise level, value at operator's ear (EN 12053) | dB(A) | 79 | 79 | 79 | 79 | 79 | 79 | 79 | |

| 8.5 | Towing coupling design / DIN type, ref. | PIN | PIN | PIN | PIN | PIN | PIN | PIN |