INTELLIGENT PERFORMANCE

INCREDIBLE PRODUCTIVITY

Smart. Safe. Agile. EDiA EM is a lot of truck in a compact package. Legendary Mitsubishi Forklift Trucks engineering, exceptional ergonomics, and cutting edge technology - like AutoBoost and Sensitive Drive System+ (SDS+) - combine to make EDiA a favourite of drivers and businesses alike.

These electric trucks offer manoeuvrability for efficient, highly productive working with incredibly tight steer angles - including the option of time-saving 360-degree steering on the three-wheel models.

The intelligent systems at the heart of the truck work to perfectly match the driver, offering precise, consistent performance that's tailored to the individual operator.

| Model | Load Capacity |

|---|---|

| FB16CN2 | 1600 kg |

| FB16N2 | 1600 kg |

| FB18CN2 | 1800 kg |

| FB18N2 | 1800 kg |

| FB20N2 | 2000 kg |

This driver-assist system responds intuitively to the individual operator's input - altering the performance characteristics for greater productivity and safety.

This ergonomically adjustable control setup makes operating far more comfortable for the driver during long shifts. This not only minimises fatigue, keeping them more focused and productive, but reduces the risk of RSI and other strains in the neck and shoulders, a common cause of driver absence which comes with related costs.

The truck senses when power is needed, and will automatically activate acceleration and torque boosts.

AHH prevents rollback even when fully loaded on very steep ramps. This makes for safer and faster loading/unloading. Operator safety is increased while improving productivity and reducing product damage.

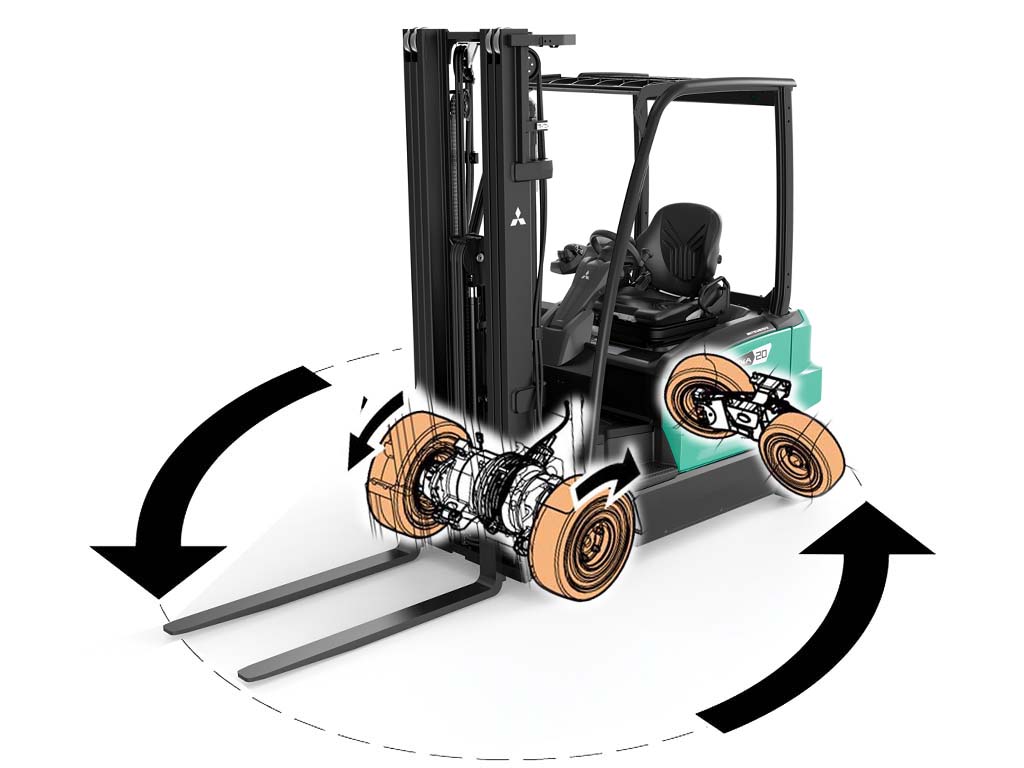

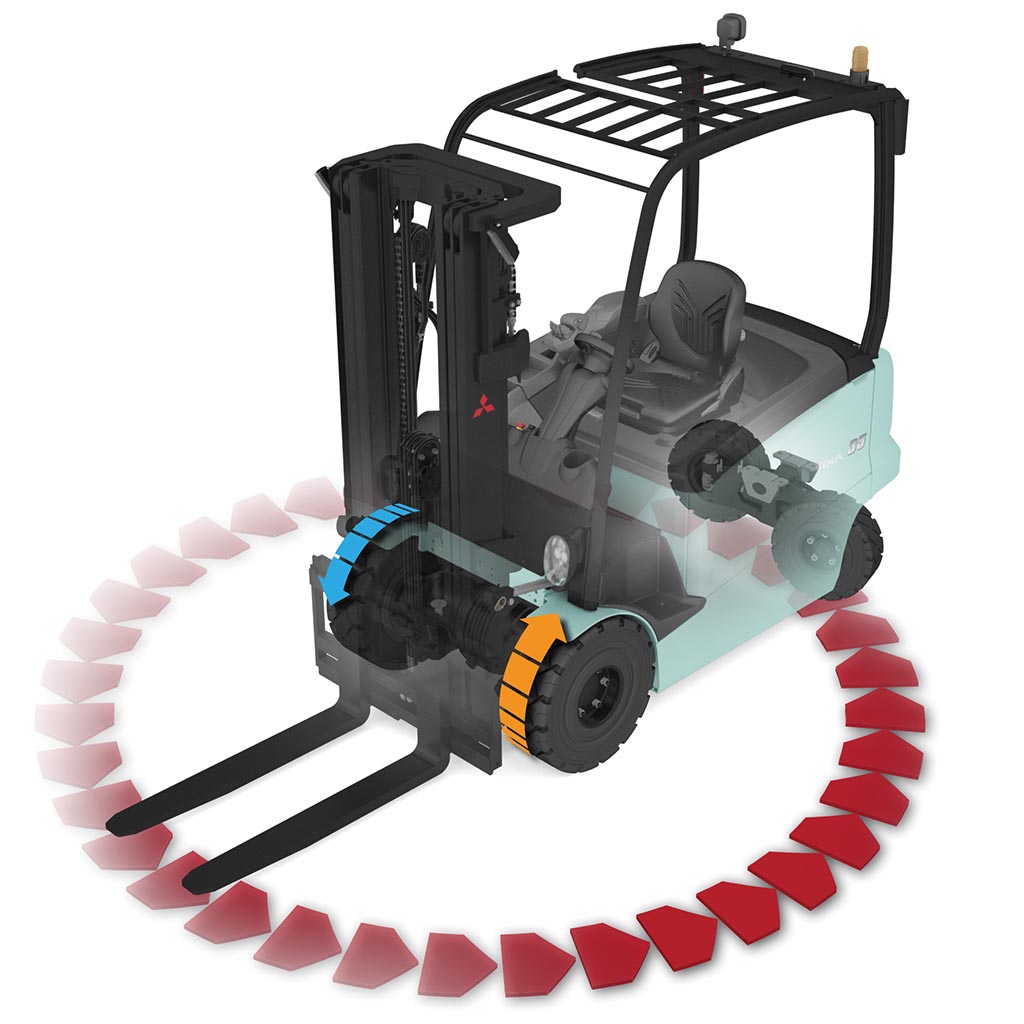

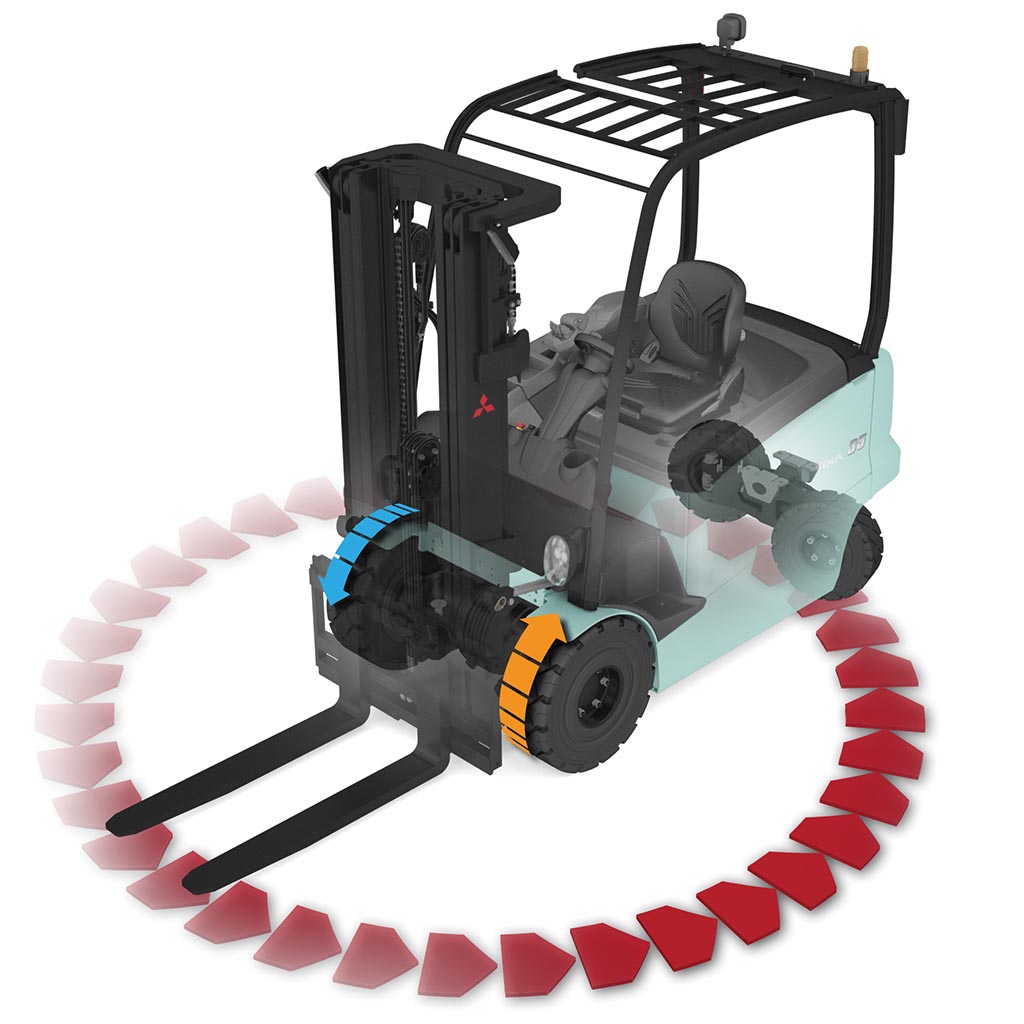

This gives better grip and manoeuvrability, particularly in tight spaces, as the truck can turn quickly and easily on the spot.

Red Dot is an internationally recognised symbol of outstanding design, marking the best in aesthetics, functionality, and innovation. The truck's next-generation design, combined with a host of outstanding features, and class-leading ergonomics greatly impressed the expert jury.

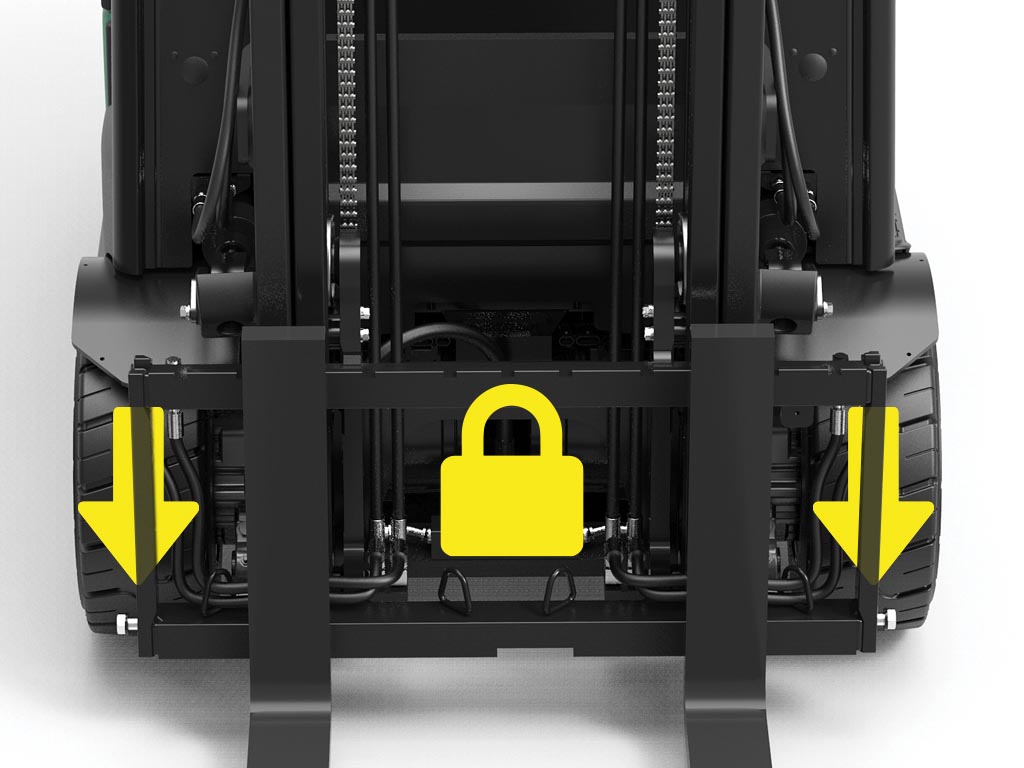

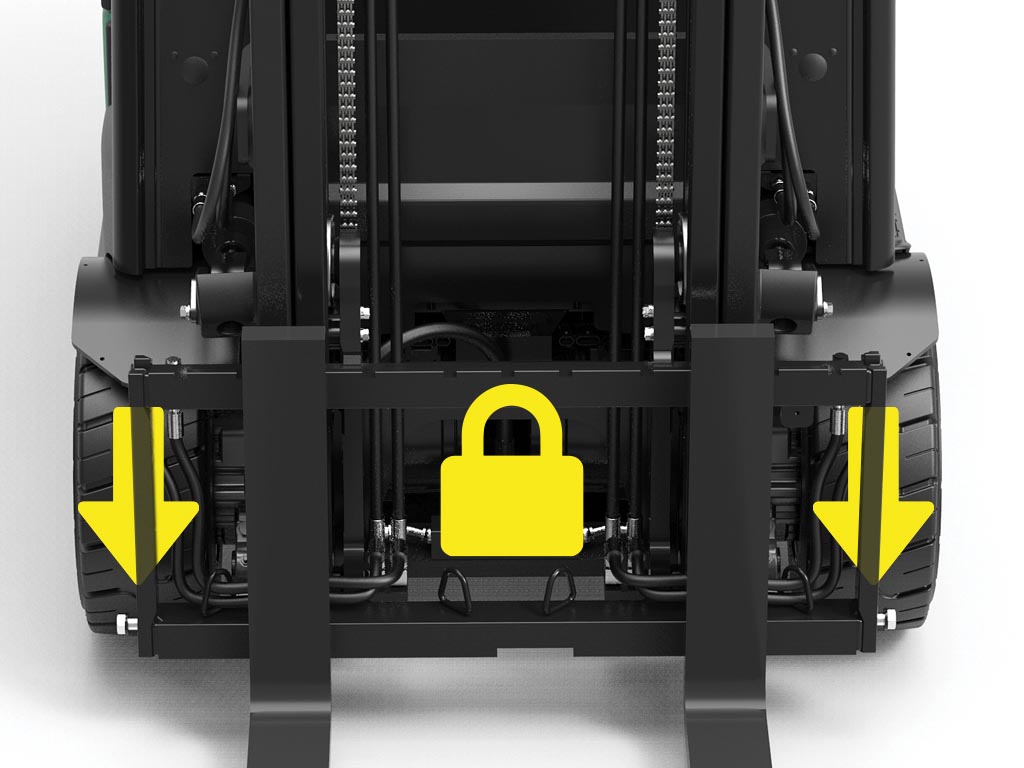

When activated, the electric differential lock will give the truck the best possible traction by spinning both front wheels, and can be preset to engage when speed is low or steering angle is limited.

This option allows for quick charging, while minimising maintenance - avoiding the need for costly extra batteries and time-consuming changeovers. (Option)

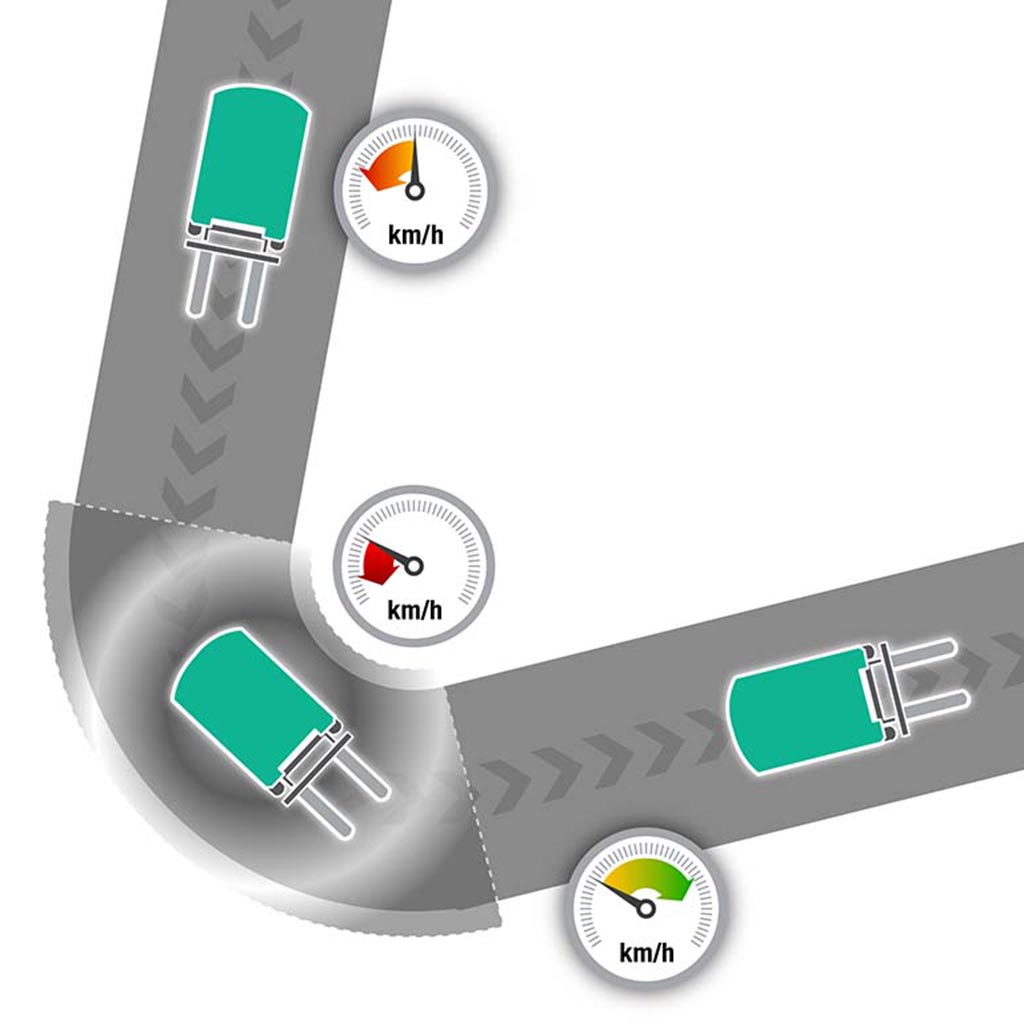

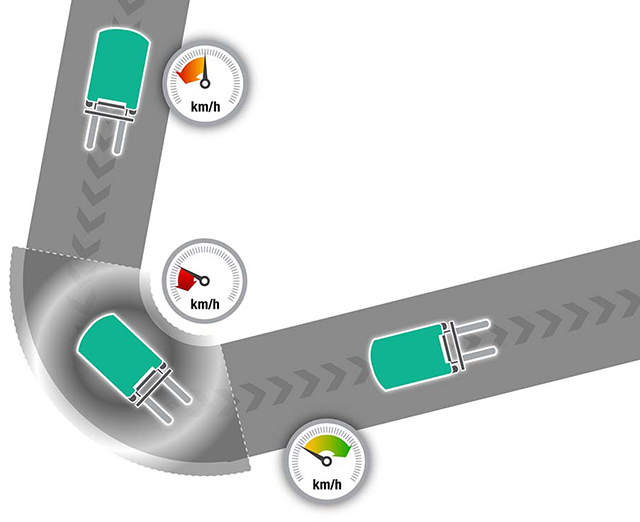

Automatically adjusts truck speed according to steer angle for increased operator and site safety, improved productivity and reduced tyre wear.

Mast sway movements are dampened by the chassis, enabling operators to lift confidently to high heights.

Offering simultaneous lift and tilt functions, the ergonomic dual joysticks have good grip, especially when used with gloves.

AutoBoost

Acceleration and torque boost functions provide more power when needed, such as on ramps.

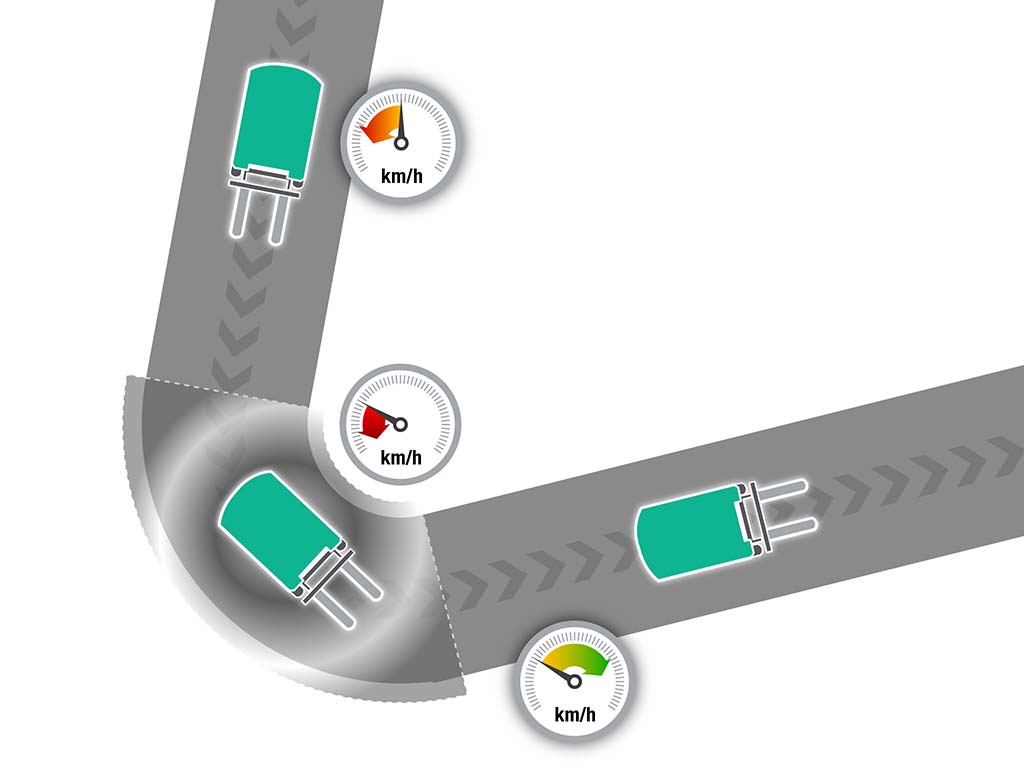

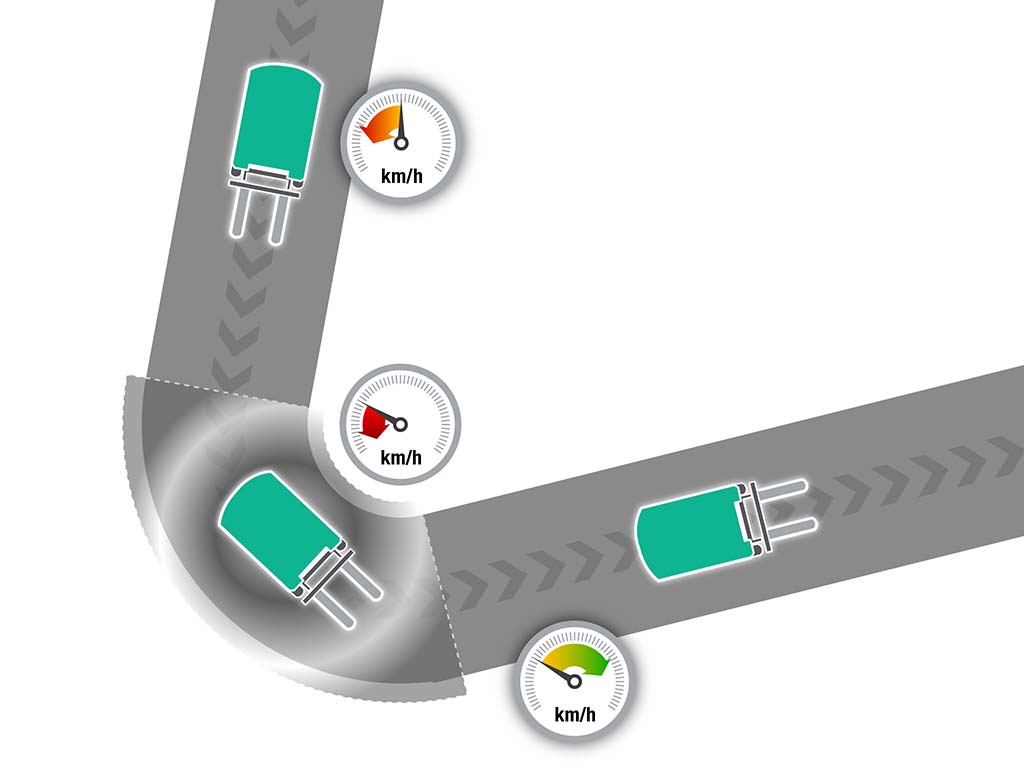

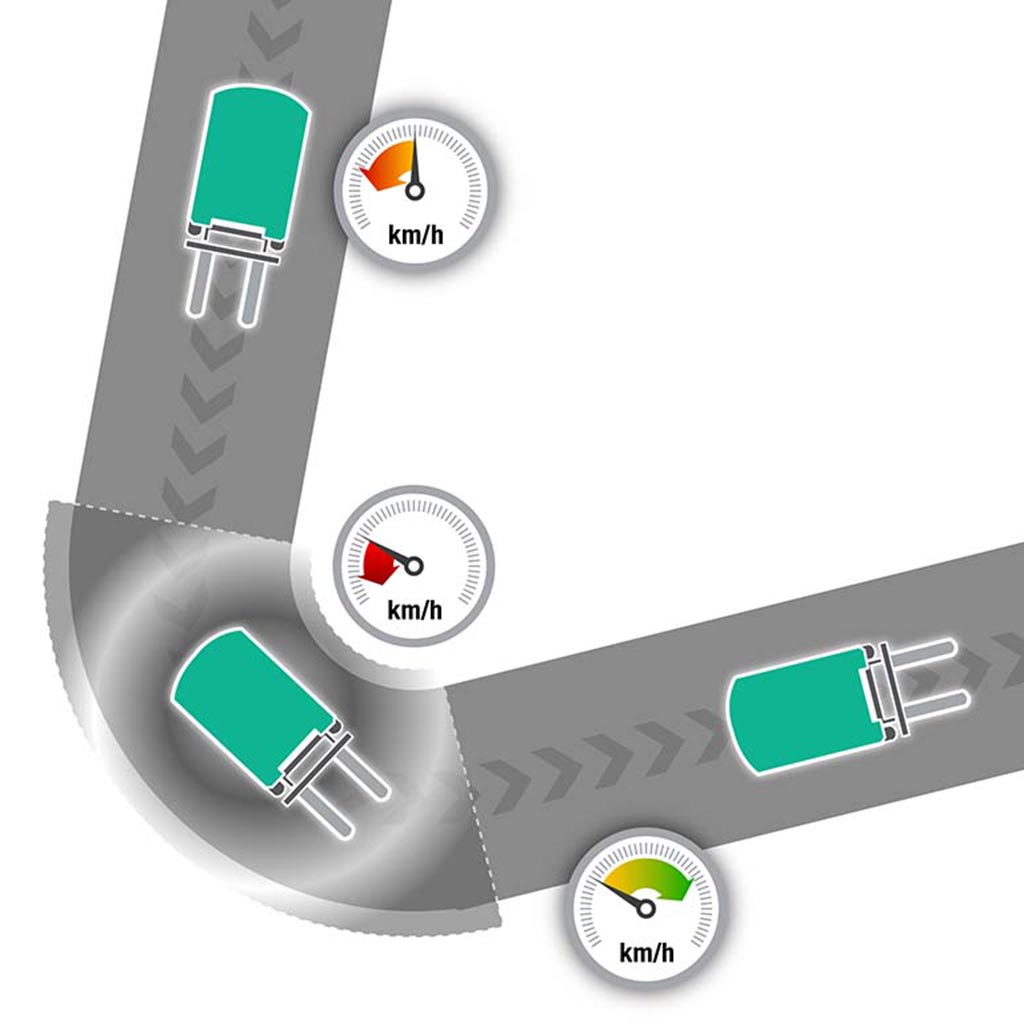

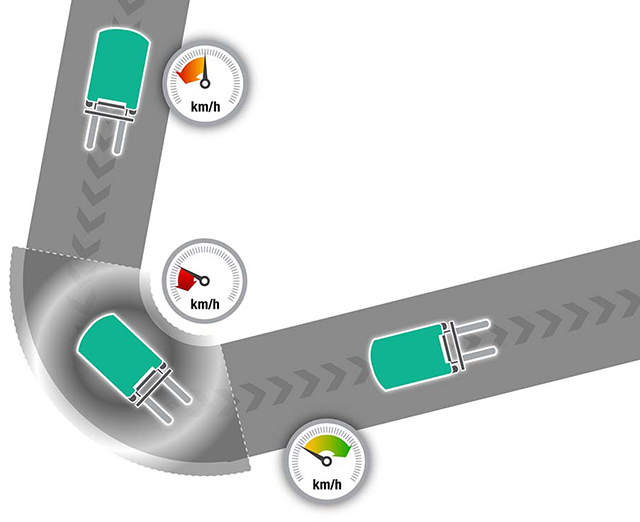

Intelligent Cornering System

The truck senses the angle of a turn and reduces speed early for maximum stability and accurate, positive cornering.

Four Wheel Steering (4WS)

Front axle drive motors turn in separate directions for better grip and precise handling. The rear axle steers through a full 100°, with dual drive motors for instant, smooth turning on the spot and no initial 'push'. This offers excellent manoeuvrability in tight spaces.

Adaptive Lift Control (ALC)

Allows truck to remain stable with fewer movements when lowering loads from high heights.

Automatic Hill Hold

The truck stops automatically when the accelerator is not engaged, preventing rolling on ramps. No need to remember to use a handle or switch.

Sensitive Drive System+ (SDS+)

Our next-generation driver-assist system for increased safety. Traction and mast performance are independently managed according to steer angle and the velocity of foot and finger controls to match driver reaction speeds.

Integrated Presence System 2 (IPS2)

Truck and mast will not move if the operator is not seated, and provides a seat belt warning light and parking brake alarm.

360° visibility

An optimised mast, wheel, dashboard and counterweight design maximises visibility to load, forks, front and rear wheels - giving safe, confident operation in tight spaces.

Passive Sway Control

Minimises mast sway, especially in high lifts above 3 m.

To get the most from operator and machine our centralised system for AC control uses advanced intelligent control, plus the latest MOSFET and heat dissipation technology for maximum performance and energy efficiency.

Offering high power for excellent traction and ramp performance, it provides smooth, quiet and controlled operation, extended shift lengths and reduced maintenance requirements.

Developed for safety, Automatic Hill Hold automatically stops your truck from rolling while manoeuvring on ramps.

It activates as soon as the operator's foot is removed from the accelerator - without separate switches or handles.

ErgoCentric describes our approach to meeting your operator's ergonomic needs.

You'll see this approach throughout the truck, but particularly in the operator's compartment where providing spacious, uncluttered access and maximum visibility are top priorities.

Helps prevent dangerously fast cornering using intelligent speed reduction from the moment the truck enters the turn, rather than kicking in harshly midway.

Sensing the angle of a turn, speed is dynamically reduced at the start of and throughout the turn for smoother, safer, and more consistent cornering.

IPS2 prevents all truck and mast movement if the operator is not seated to prevent accidental lifting, lowering, tilting and travel. An electronic parking brake is applied automatically if the seat is empty and this can also be done manually via a dashboard button.

In addition, the system automatically gives operators essential warnings and reminders to encourage safety.

To ensure maximum productivity at any height, this model is equipped with Passive Sway Control.

This feature dampens the elevated load motion that can occur when carrying loads at height.

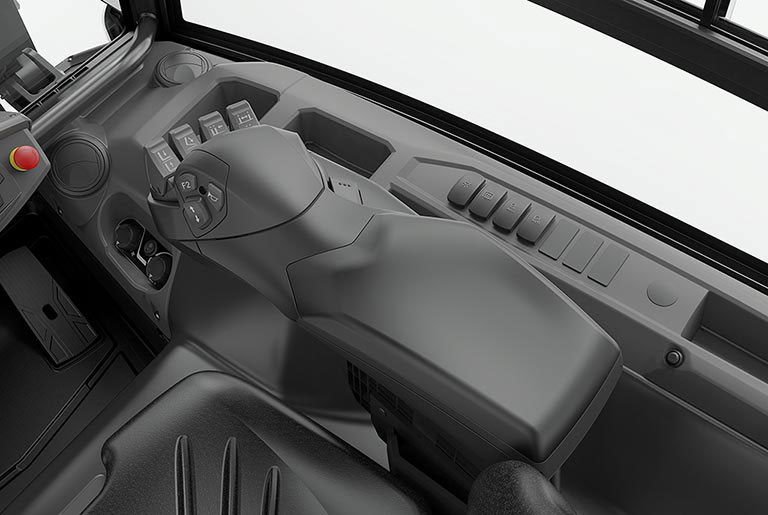

The fully adjustable, full-length ergonomic armrest allows for a more natural arm position and offers excellent support, reducing the risk of RSIs associated with intensive operations. A variety of control schemes can be specified to match different applications:

Fingertip controls

Ideal for applications where precise control is needed, they can even be operated using protective gloves.

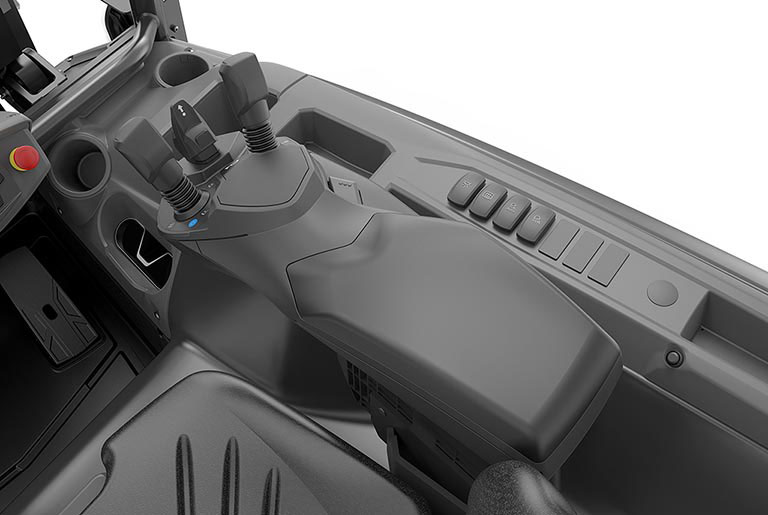

Dual joysticks

These offer simultaneous functions for lift and tilt, and their settings can easily be customised to specific requirements.

Ergologic joystick

This intuitive and highly ergonomic single joystick can control seven different functions, including lifting, lowering, reaching, and tilting.

Tried, tested and proven in the field, lead-acid batteries have been the long-standing choice for companies employing electric lift trucks. However, with long charging times, demanding maintenance requirements, the need for extra batteries, and high risk of operator misuse, it can be a challenge. Fortunately, there's a new battery system on the block: Li-ion from Mitsubishi Forklift Trucks.

Designed to meet your business' demands - including multi-shift (24/7) operations - without the need for spare batteries, our high-performance Li-ion battery system is up to 40 per cent more efficient than lead-acid counterparts. Plus, it's virtually error-proof, thanks to its ultra-low-maintenance design which prevent cell damage.

Exceptional, zero-emissions efficiency

40% more efficient than lead-acid batteries and free from gases.

Ultra-low maintenance design

Just a full charge each week to activate cell balancing, as well as an annual CSV export/update.

No space required

With no need for charging areas, there's no cost for set up and you can keep your profitable space just that: profitable.

Quick charge capabilities

Just 15 minutes is all your battery needs to keep your truck going a few more hours. (It only takes 1 to 2 hours to fully charge a completely discharged battery.)

Higher sustained voltage

This ensures more consistent lifting and driving performance, which is particularly noticeable towards the end of a shift.

TriCOM Technology

Helps to deliver exceptionally high system efficiency (up to 97%)

| Characteristics | ||||||||

| 1.2 | Manufacturer's model designation | FB16CN2 | FB16N2 | FB18CN2 | FB18N2 | FB20N2 | ||

| 1.3 | Power source: (battery, diesel, LP gas, petrol) | Electric | Electric | Electric | Electric | Electric | ||

| 1.4 | Operator type: pedestrian, (operator)-standing, -seated | Seated | Seated | Seated | Seated | Seated | ||

| 1.5 | Load capacity | Q | kg | 1600 | 1600 | 1800 | 1800 | 2000 |

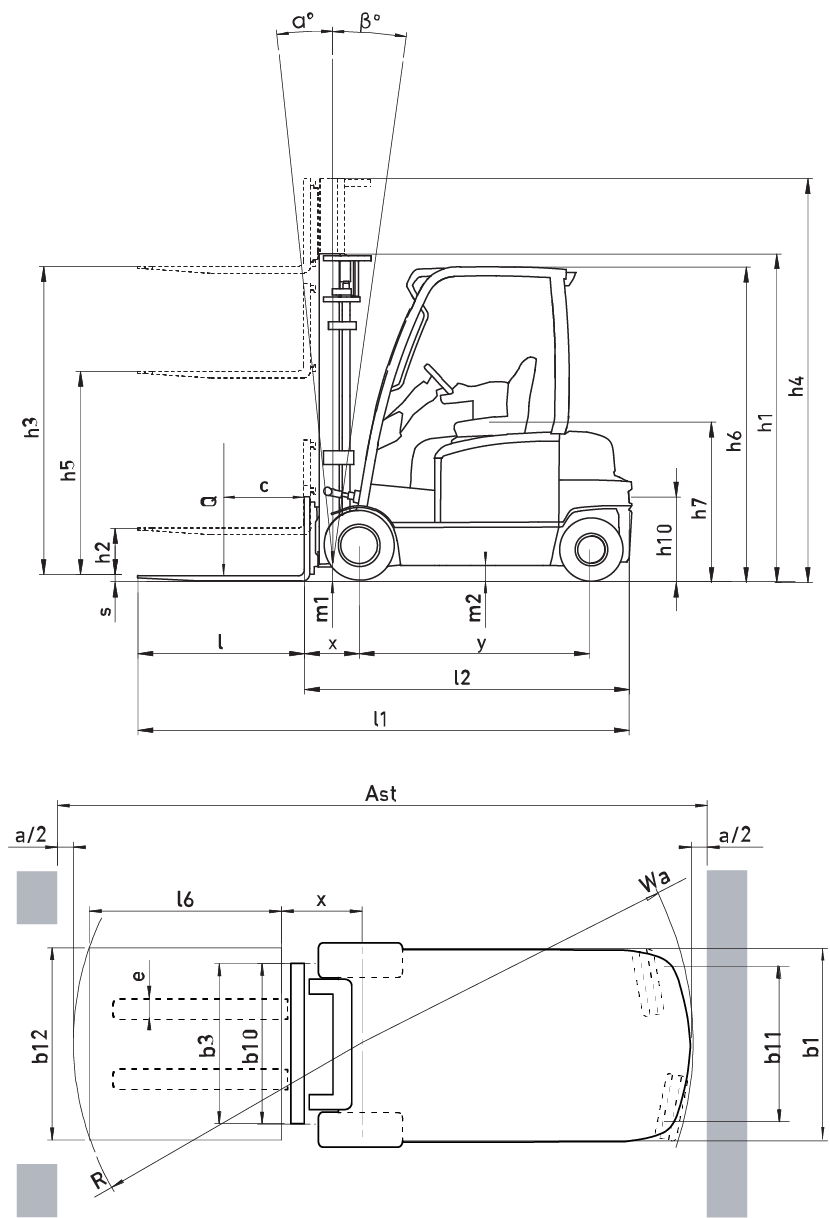

| 1.6 | Load centre distance | c | mm | 500 | 500 | 500 | 500 | 500 |

| 1.8 | Load distance, axle to fork face (forks lowered) | x | mm | 343 | 343 | 343 | 343 | 358 |

| 1.9 | Wheelbase | y | mm | 1394 | 1502 | 1394 | 1502 | 1502 |

| Weight | ||||||||

| 2.1 | Truck weight without load, with maximum battery weight | kg | 2944 | 2957 | 3114 | 3097 | 3287 | |

| 2.2 | Axle loading with maximum load, front/rear (simplex mast, lowest lift height) | kg | 3990 / 554 | 4008 / 550 | 4311 / 603 | 4295 / 603 | 4668 / 620 | |

| 2.3 | Axle loading without load, front/rear (simplex mast, lowest lift height) | kg | 1422 / 1522 | 1510 / 1448 | 1422 / 1692 | 1484 / 1613 | 1525 / 1762 | |

| Wheels, Drive Train | ||||||||

| 3.1 | Tyres: V=solid, L=pneumatic, SE=solid pneumatic - front/rear | SE | SE | SE | SE | SE | ||

| 3.2 | Tyre dimensions, front | 18 × 7–8 | 18 × 7–8 | 18 × 7–8 | 18 × 7–8 | 200 / 50–10 | ||

| 3.3 | Tyre dimensions, rear | 16 × 6–8 | 16 × 6–8 | 16 × 6–8 | 16 × 6–8 | 16 × 6–8 | ||

| 3.5 | Number of wheels, front/rear (x=driven) | 2 x / 2 | 2 x / 2 | 2 x / 2 | 2 x / 2 | 2 x / 2 | ||

| 3.6 | Track width (center of tyres), drive side | b10 | mm | 930 | 930 | 930 | 930 | 938 |

| 3.7 | Track width (center of tyres), load side | b11 | mm | 898 | 898 | 898 | 898 | 898 |

| Dimensions | ||||||||

| 4.1 | Mast tilt, forwards/backwards | a / b | ° | 5/7.5 | 5/7.5 | 5/7.5 | 5/7.5 | 5/7.5 |

| 4.2 | Height with mast lowered (see tables) | h1 | mm | 2125 | 2125 | 2125 | 2125 | 2125 |

| 4.3 | Free lift (see tables) | h2 | mm | 80 | 80 | 80 | 80 | 80 |

| 4.4 | Lift height (see tables) | h3 | mm | 3290 | 3290 | 3290 | 3290 | 3290 |

| 4.5 | Height with mast extended | h4 | mm | 4335 | 4335 | 4335 | 4335 | 4335 |

| 4.7 | Height to top of overhead guard | h6 | mm | 2050 | 2050 | 2050 | 2050 | 2050 |

| 4.8 | Seat height | h7 | mm | 1035 | 1035 | 1035 | 1035 | 1035 |

| 4.12 | Tow coupling height | h10 | mm | 520 | 520 | 520 | 520 | 520 |

| 4.19 | Overall length | l1 | mm | 3152 | 3260 | 3152 | 3260 | 3275 |

| 4.20 | Length to fork face (includes fork thickness) | l2 | mm | 2002 | 2110 | 2002 | 2110 | 2125 |

| 4.21 | Overall width | b1/b2 | mm | 1090 | 1090 | 1090 | 1090 | 1140 |

| 4.22 | Fork dimensions (thickness, width, length) | s,e,l | mm | 35x100x1150 | 35x100x1150 | 35x100x1150 | 35x100x1150 | 35x100x1150 |

| 4.23 | Fork carriage to DIN 15 173 A/B/no | 2A | 2A | 2A | 2A | 2A | ||

| 4.24 | Fork carriage width | b3 | mm | 920 | 920 | 920 | 920 | 920 |

| 4.31 | Ground clearance under mast, with load | m1 | mm | 95 | 95 | 95 | 95 | 95 |

| 4.32 | Ground clearance at centre of wheelbase, with load (forks lowered) | m2 | mm | 95 | 95 | 95 | 95 | 95 |

| 4.33 | Working aisle width with 1000 × 1200 mm pallets, crosswise | Ast | mm | 3333 | 3441 | 3333 | 3441 | 3455 |

| 4.34 | Working aisle width with 800 × 1200 mm pallets, crosswise | Ast | mm | 3456 | 3564 | 3456 | 3564 | 3579 |

| 4.35 | Turning circle radius | Wa | mm | 1662 | 1770 | 1662 | 1770 | 1770 |

| 4.36 | Minimum distance between centres of rotation | b13 | mm | 0 | 0 | 0 | 0 | 0 |

| Performance | ||||||||

| 5.1 | Travel speed, with/without load | km/h | 17/17 | 17/17 | 17/17 | 17/17 | 17/17 | |

| 5.2 | Lifting speed, with/without load | m/s | 0,52/0,62 | 0,52/0,62 | 0,46/0,62 | 0,46/0,62 | 0,62/0,42 | |

| 5.3 | Lowering speed, with/without load | m/s | 0,56/0,56 | 0,56/0,56 | 0,56/0,56 | 0,56/0,56 | 0,56/0,56 | |

| 5.5 | Rated drawbar pull, with/without load | N | 4900/5200 | 4900/5200 | 4800/5100 | 4800/5100 | 4700/5100 | |

| 5.6 | Maximum drawbar pull, with/without load (5 min short duty) | 14900/15200 | 15000/15300 | 14900/15200 | 14900/15200 | 14800/15200 | ||

| 5.7 | Gradeability, with/without load | % | 15/25 | 15/26 | 14/23 | 14/23 | 12/21 | |

| 5.8 | Maximum gradeability, with/without load | s | 27/35 | 27/35 | 26/35 | 26/35 | 24/35 | |

| 5.9 | Acceleration time (10 metres) with/without load | s | 4.1 / 3.8 | 4,0/3,8 | 4,2/3,8 | 4,2/3,8 | 3,9/4,4 | |

| 5.10 | Service brakes (mechanical /hydraulic /electric /pneumatic) | Electric | Electric | Electric | Electric | Electric | ||

| Electric Motors | ||||||||

| 6.1 | Drive motor capacity (60 min. short duty) | kW | 2x5,5 | 2x5,5 | 2x5,5 | 2x5,5 | 2x5,5 | |

| 6.2 | Lift motor output at 15% duty factor | kW | 10 | 10 | 10 | 10 | 10 | |

| 6.3 | Battery to DIN 43 531/35/36 A/B/C/no | DIN 43531 A/no | DIN 43531 A/no | DIN 43531 A/no | DIN 43531 A/no | DIN 43531 A/no | ||

| 6.4 | Battery voltage/capacity at 5-hour discharge | V/Ah | 500-625 | 625-750 | 500-625 | 625-750 | 625-750 | |

| 6.5 | Battery weight | kg | 679 | 679 | 679 | 812 | 812 | |

| Miscellaneous | ||||||||

| 8.1 | Type of drive control | AC | AC | AC | AC | AC | ||

| 8.2 | Maximum operating pressure for attachments | bar | 210 | 210 | 210 | 210 | 210 | |

| 8.3 | Oil flow for attachments | L/min | 30 | 30 | 30 | 30 | 30 | |

| 8.4 | Noise level, value at operator's ear (EN 12053) | dB(A) | 65 | 65 | 65 | 65 | 65 | |

| 8.5 | Towing coupling design / DIN type, ref. | DIN15170-H | DIN15170-H | DIN15170-H | DIN15170-H | DIN15170-H |